Jam is made up of fruit juices, fruit pulp, fruit juice concentrate or dry fruit. These pieces of fruit or the pulp or juice are boiled along with sweeteners, namely sugar, dextrose, invert sugar or liquid glucose to a suitable concentration. It can be prepared by adding a combination of fruit pieces together or also with one specific fruit. An entirely made jam will contain favours of the fruit(s) used for manufacturing and will be free from any additional burnt or undesirable flavour and crystallized sugar.

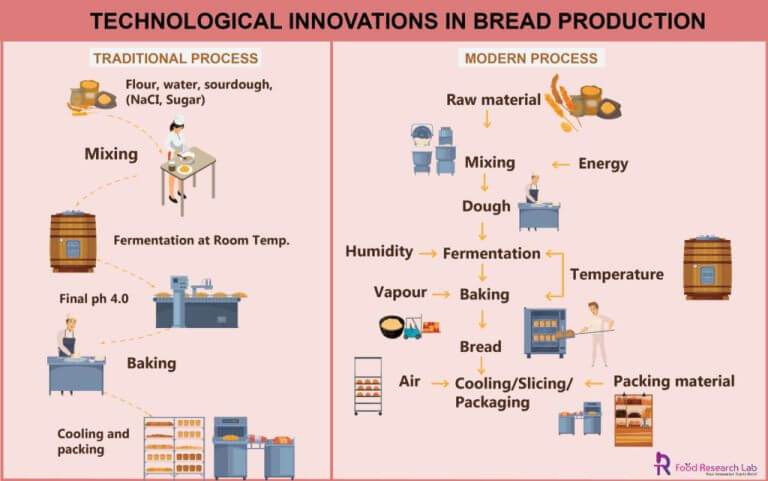

Technological innovations in Bread Production

In Brief:

- Consumption of bread is the primary source of food for many countries around the world. So it is a challenge to all therecipe developing services to formulate a new methodology that gives high-quality gluten-free bread.

- The food product development companies should be promising to deliver enhanced bread properties, gaining trust among the people.

- For the process of the food research lab is here to help you understand with the new technological innovations in the bread production.

Introduction

Bread is on the most common food consumed by all parts of the world over thousands of years. Yeast is the most integral ingredient in bread production. As a primary food source of the world’s population, bread production should be healthier and cost-efficient. Gluten is the main structure of the protein that adds quality in bread’s viscoelasticity. Gluten contains high protein content, so to replace gluten in bread production remains challenging still now. Food development consultants had a series of discussions and started to try new product development in the food industry. Replacement of gluten is essential as it leads to coeliac diseases for humans.(1)

Innovative technologies in bread production

The particular focus of bread production using technologies is to produce gluten-free bread products. Though many innovations on bread productions formulate, to improve the bread quality with gluten-free ingredients, it is in vain. Some amount of gluten network is partially imitating in bread production. Many food development industries and new product development companies are not paying attention to overcome this problem. New innovative technological approaches are here to make a loaf of gluten-free bread in the food development companies to alter the consistency of the batter.

(2)

Sourdough technology

Sourdough is a traditional method and still many food development consulting services belives sourdough is an ultimate source to produce GF bread. The demand for alternative technologies in bread production is to expel the inclusion of additives in bread production. Reduction of food additives will reduce the raw material costs avoids the entry of allergens in the product.

The by-products such as exopolysaccharides lactic acids during fermentation gives some positive effects to the food development company. Here the lactic acid and acetic acid attributes to the dough properties that lead in producing soft bread and increases protein stability. The lactic acid and acetic acid ratio determine the aroma of bread. Metabolites obtained using this technology( Carbondioxide, ethanol, fungicide, fatty acids) helps in the preservation

(3)Common bacterial strains used in sourdough production

- L. Plantarum

- L. casei or L. fermentum

- L. Reuteri

- L. Paralimentarius

These microbial strains help to increase the quality of GF bread. Hence sourdough is considering to be a promising technology that improves

- Sensorial

- Nutritional

- Texture

- Quality

- The aroma of the bread.

High hydrostatic pressure

High hydrostatic pressure(HHP) is a new modern process that helps in the non-thermal preservation of fruit juices. HHP has many functional properties. Out of all, it modifies the properties of protein and starch that alters the rheology of the product. It increases the starch’s swelling with modifications in structure without changing the granule’s probity. This primary function of HHP leads to alter the viscoelastic behaviour and change the entire action of starch and differs in water content present in the sample. The effect of HPP varies on the structure formation, mainly gluten content present in the dough used by the food production companies. The viscoelastic properties of the gluten-free bread increase by inducing starch gelatinization and crosslinking of proteins made from buckwheat. It gives innovation technologies in bread production. Oat bread also uses this technology by many food development industries.

(4)Applications of high hydrostatic pressure

- Increases batter elasticity

- Increase volume

- Increase the texture of the bread

Non-convenient bread production technologies

New technologies are rising in the field of bread production with heating technologies by the baking industries.

Advantages

- Low processing costs

- Production time is less

- Enhance bread properties

Appropriate heating techniques will help in achieving the benefits. Some of the non-convenient heating techniques are

- Microwave

- Infrared

- Jet-impingement

- Ohmic heating

- Hybrid heating

These heating techniques will help to gain a rapid structure and desired bread quality with no moisture loss, higher crumb firmness, lower starch granule disintegration, decreased gelatinization.

Conclusion

Though many technological innovations approach in the bread production companies, it remains a challenge to offer a healthy and quality enhanced bread to the people. The bread production in food industries should consider these techniques given by food research lab and come up with new product development in the food industries. The production of gluten-free loaves of bread is mandatory in this pandemic world as many people around the world consuming bread as their primary source of food.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.