INTRODUCTION

Thermal methods have the potential to produce high-quality foods affordably, and radio-frequency heating is a component of novel electromagnetic heating techniques. The two types of electro-heating are direct electro-heating (e.g., ohmic heating (OH)), where electrical current is applied directly to the food, and indirect electro-heating (e.g., microwave (MW) or radio frequency (RF) heating), where electrical energy is first converted to electromagnetic radiation that then generates heat inside the product.

The molecules inside a product are constantly reoriented in an RF environment (27 million times/s at 27 MHz) in reaction to the applied field. This is how radio frequency heating works. Due to the frictional contact between the molecules, this reaction starts volumetric heating throughout the entire product, which selectively warms just the product and not the air or surrounding equipment [1].

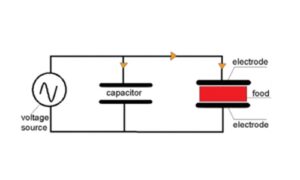

Figure 1: A schematic diagram of a Radiofrequency heating (RF-H) system [1]

Principle Mechanism of Heating

The RF generator in a radio-frequency heating (RF-H) system produces an alternating electric field between two electrodes.

The material to be heated is positioned in the space between the electrodes, where the alternating energy induces polarisation in the molecules, causing them to reposition themselves towards the opposing poles repeatedly.

In other words, ionic conduction and dipolar relaxation are the two main processes involved in energy absorption.

Dipolar water molecules strive to follow the electric field associated with electromagnetic radiation as it oscillates at very high frequencies, releasing heat. Ions in the food oscillate and move around, producing heat as a secondary heating process.

The frequency, the square of the applied voltage, the product’s dimensions, and the material’s dielectric loss factor—a measure of how easily radio waves can heat the material—all affect how much heat is produced in the product. Electricity is used to power an RF generator, amplifying its signal and sending it to a parallel electrode system (RF cavity) where the chosen material is installed, producing RF power [2].

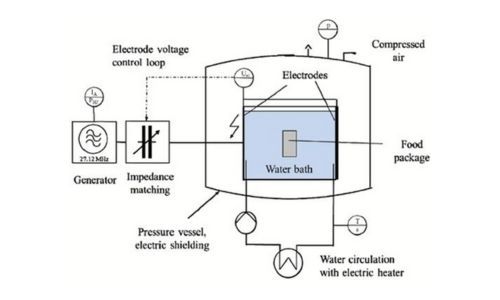

Figure 2: A water bath could treat heat-sensitive substances like yoghurt using RF-H [1]

Application of Radio Frequency

Due to its potential to raise food product quality, radio frequency heating has a wide range of uses in the food business.

- Baking: When Radio-frequency methods were used for baking, it was noticed that there was a volumetric cooking of the product and not from only one side that caused overcooking. Cooking using this method saves time and energy, maintaining food quality [3]. In addition, radiofrequency heating significantly reduces the cracks in products like cookies and crackers since there is an even distribution of energy, preventing the difference in moisture content at different parts of the product [4].

- Blanching: Radiofrequency heating method can inactivate enzymes like polyphenol oxidases, peroxidase, catalase, and phenolase, preventing browning and generating off-flavours in food. In addition, it can retain water–soluble nutrients that can be lost by conventional blanching methods [3].

Figure 3: Radiofrequency ensures the quality of baked products like cookies and crackers [3]

3.Drying: RF heating has been employed in various drying applications, including the post-baking drying of cookies, crackers, and snack items, which offers benefits over traditional drying and microwave drying. The device, which ran at 6.5 to 7.8 kW at 60 MHz, could roast cocoa beans to a temperature of 130°C and lower their moisture content from 6% to 1%. The electrodes of the vertical RF dryer were designed to form two nested cylinders, with material passing through the annular area between the electrodes.

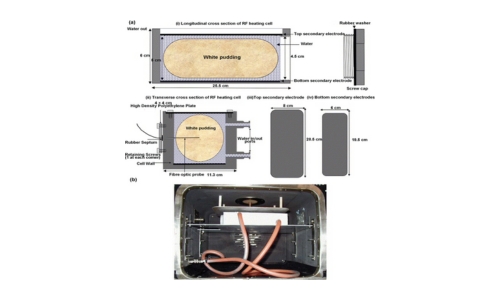

4. Processing meat: Using the RF unit considerably reduced the processing time, meat quality, and juice losses compared to conventional hot water processing. Additionally, processing 0.91 kg of lean ham heated at 60 MHz in a condenser tunnel only took a third as long with the RF unit. Compared to conventional processing using hot water, the results showed that juice losses decreased and quality significantly improved. At the same pasteurisation levels as conventional heat treatments, RF heat treatments have been shown to have harmful effects on tested organisms; nevertheless, RF-treated meat had superior quality, coagulated better, and had good flavour and appearance [1].

Figure 4 (a)- A diagram of the RF heating unit

Figure 4 (b)- Hot water is circulated in a Radio Frequency oven [3]

Advantage

- It prevents the surface of the food product from becoming too hot.

- It allows for both contactless and deep heating of food.

- A device that utilises RF energy, like a microwave oven, provides quick heating and takes little time.

- Ovens that use RF energy are economical and conserve power.RF cooking produces cooked food that is savoury and sanitary.

Disadvantage

- In comparison to ohmic heating devices, RF energy-based cooking appliances are more costly[1].