INTRODUCTION

- The pharmaceutical, food, cosmetic, textile, personal care, agricultural, chemical, biotechnology, biomedical, and sensor sectors have researched microencapsulation extensively. Growing research in this field can be attributed to the fact that microencapsulation can be used to formulate value-added products.

- The global cosmetics and personal care products business is valued at several billion dollars and has grown significantly. With more and more uses in this industry, microencapsulation has been employed to create more reliable, efficient cosmetic formulations with superior sensory qualities.

- Sunscreens, perfumes, moisturising, tanning, whitening and anti-ageing agents are a few examples that have been studied for microencapsulation. Other areas studied for microencapsulation include formulation and stabilisation of topical medicines, recent and upcoming advancements, challenges, and future developments [1].

Cosmetic active ingredients encapsulated for topical application

- Microencapsulation has been extensively studied in skincare and beauty products for their application. Vitamin A (VA), or retinol, is an antioxidant in skincare products.

- Examples include Vitamin A serum (retinol face serum), retinol face wash, retinol hand cream, retinol peel and retinol cream for pigmentation.

- It restores skin suppleness and reduces flaking, thereby reducing skin dryness and improving skin health.

- Jenning and others evaluated the potential applications of Solid Lipid Nanoparticles (SLN) in cosmetics and dermatology by encapsulating VA in glyceryl behenate SLN via melt solidification [2].

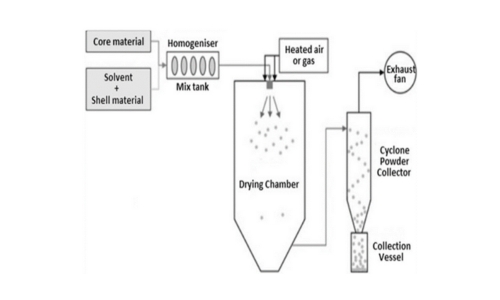

Figure 1: Schematic diagram of microencapsulation technique [1]

Microencapsulation in cosmetics

- The cosmetics and personal care industries rely heavily on delivery systems and microcapsules. They provide an ideal and one-of-a-kind carrier system for active ingredients, making it possible to release, isolate, and protect active ingredients, making the formulations more viable, masking undesirable aspects like the smell and enhancing the properties and appearance of the product.

- Microencapsulation can be used to formulate shower and shower gels, moisturisers and creams, hair care products, sunscreens and tanning creams, cosmetics, fragrances, cleansers and exfoliants [3].

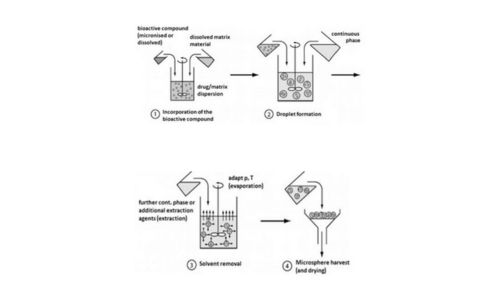

Figure 2: Schematic diagram of the encapsulation process [3]

Encapsulating materials for cosmetic applications

- The core material encapsulated is the active ingredient to be used, and the material depends on the final cosmetic product where the capsules will be incorporated and the desired function.

- Other factors considered for choosing an encapsulation material are chemical and physical stability, mechanism of release of the active ingredient, concentration and particle size.

- Toxicity, biocompatibility, stability, viscosity, and mechanical properties, compatibility between the active ingredient and the wall material, the release of the active ingredient into the skin from the vehicle, enhancement of active penetration into the stratum corneum, intended particle size and microscopic properties of the surface of the microparticles, as well as the processing and economic factors, should all be taken into consideration when selecting a wall material for use in topical applications.

- The right decision of the shell material is fundamental as it impacts the efficacy and protection of the microcapsules.

- Commonly used core materials in cosmetic products for topical application have been reviewed. Encapsulating materials can be chosen from biodegradable and non-biodegradable polymers. Extensive research has been conducted on protecting active agents in micro-sized carriers for controlled release over time.

- Natural and biodegradable biopolymers like chitosan are preferred as encapsulating materials. When in contact with human tissues, these natural materials are non-toxic, non-reactive, and can be broken down, metabolised, and eliminated. Other polymers studied include aliphatic polyesters like poly(lactic acid) (PLA), and copolymers of lactic and glycolic acids like PLGA (poly(lactic-co-glycolic acid)) are the encapsulating materials that are more popular for use in skin delivery systems.

- However, the structure of chitosan can be altered to produce water-soluble chitosan, which is easily soluble in neutral aqueous solutions and expands the compound’s application range[4].

Conclusion:

- Consumers’ demand for improved efficacy and safety of the products has fuelled an interest in more complex and sophisticated products.

- Microencapsulation of active ingredients has become increasingly popular in cosmetics and personal care products since the functionality of the active ingredients can be enhanced, and the product has added value. In addition, technological advancements have made microencapsulation more feasible.