Benefits of Reverse Engineering of Nutraceuticals

Introduction

Nutraceuticals have become increasingly popular in recent years since they offer a plethora of health benefits. Various types of nutraceuticals have been developed that have been formulated from different ingredients, including aloe vera, chia oil, flax seed oil and algae in the form of nutraceutical capsules and nutraceutical tablets. However, ensuring quality becomes quintessential for nutraceuticals to be successful in today’s highly competitive market. This is where reverse engineering comes into play. Reverse engineering helps minimise potential risks and formulate products with safer ingredients, significantly improving the quality of nutraceuticals.

Also called backward engineering and deformulation, reverse engineering is a process wherein a product is studied for its components, and a product with similar composition is developed. The process was initially conceptualised for hardware products but was soon initiated in other specialities, like reverse engineering food, beverage products and pharmaceuticals. Reverse engineering has gained importance in the nutraceutical sector as well.

Why reverse engineering is required in the nutraceutical industry?

Deformulation or reverse engineering is valuable in the product development process and evaluation. Nutrition and nutraceutical companies can assess the products formulated by their competitors. They can develop a generic version of their products or identify functional replacements for any substances that have become obsolete.

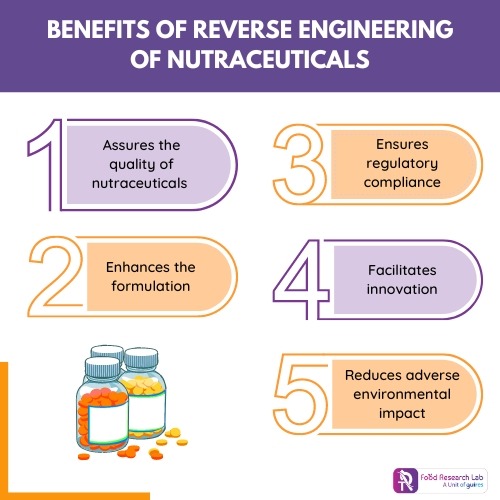

In addition, reverse engineering of nutraceuticals offers the following benefits:

1. Assures the quality of nutraceuticals

Reverse engineering aids in the quality assurance of nutraceutical products. By examining the composition of nutraceuticals, nutraceutical companies and regulatory authorities can discover any impurities or dangerous compounds added to nutraceuticals, thereby preventing product recall. Furthermore, they may ensure that health claims on nutraceutical product labels are accurate, assisting nutraceutical companies in meeting regulatory standards. Nutraceutical companies can also compare their goods to those of their competitors, assisting them in maintaining quality standards that are critical to their success. Reverse engineering allows nutraceutical companies to gain a deeper understanding of the manufacturing process, leading them to implement robust quality control measures by identifying control points and monitoring product consistency. This helps main the quality of the products.

2. Ensures regulatory compliance of nutraceuticals

The international regulatory landscape undergoes numerous revisions leading to amendments. Reverse engineering allows for analysing the composition and manufacturing processes, and manufacturers can make sure that the nutraceutical products meet the regulations regarding the recommendations for composition, manufacturing and labelling. Meeting international regulatory standards increases transparency and trust among regulatory bodies and consumers, which is crucial for a product’s success.

3. Enhances the formulation of nutraceuticals

Reverse engineering helps nutraceutical companies obtain information regarding the formulation of nutraceutical products. Nutraceutical companies can improve the efficacy of their formulations by analysing the composition and quantity of the ingredients and significantly lowering the chances of failure of nutraceuticals. Reverse engineering can help them to develop more effective nutraceuticals that meet consumer preferences.

4. Facilitates innovation of nutraceuticals

Reverse engineering opens avenues for the development of innovative products. Researchers gain valuable information from studying existing products and develop novel formulations that can be used to formulate functional foods and nutraceuticals. Of particular interest is the development of medical foods and functional foods for preventing and treating certain illnesses like obesity, cardiovascular diseases, type II diabetes and cancer. Furthermore, reverse engineering increases the scientific knowledge of nutraceuticals by assisting researchers in discovering the mechanisms of action and prospective therapeutic applications of these products. Few examples of innovative nutraceuticals that were developed from reverse engineering include whey protein gummies and moringa gummies.

5. Reduces adverse environmental impact

Reverse engineering allows nutraceutical companies to improve the processing parameters for nutraceutical formulation and helps them develop more efficient manufacturing systems that reduce their adverse effects on the environment. Sustainable practices benefit companies since they reduce waste, and consumers prefer more eco-friendly products. Ann example of sustainable practice is using enzyme assisted extraction for extracting polyphenols and bioactive compounds for formulating nutraceuticals

6. Helps protect the intellectual property of nutraceutical companies

Many counterfeit nutraceutical products are available in the market, which can pose a severe risk to consumers’ health and tarnish the brand image of nutraceutical companies. Reverse engineering helps differentiate counterfeit products from genuine ones by providing a detailed analysis of genuine products [1].

Conclusion

Reverse engineering offers numerous benefits to nutraceutical companies by helping them to assure their quality, ensure regulatory compliance, enhance product quality, facilitate innovation, reduce adverse environmental impacts and recognise counterfeit products.

How the Food Research Lab can help

We are a team of formulation experts that offer nutraceutical formulation services. We help create a new product or reformulate an existing product by reverse engineering. We exercise caution at every step, from selecting the ingredients to assisting our clients regarding the product label, ensuring that the health claims are backed by scientific evidence, improving adherence to regulations and increasing the chances of a product’s success. ealth benefits. Various types of nutraceuticals have been developed that have been formulated from different ingredients, including aloe vera, chia oil, flax seed oil and algae in the form of nutraceutical capsules and nutraceutical tablets. However, ensuring quality becomes quintessential for nutraceuticals to be successful in today’s highly competitive market. This is where reverse engineering comes into play. Reverse engineering helps minimise potential risks and formulate products with safer ingredients, significantly improving the quality of nutraceuticals. Also called backward engineering and deformulation, reverse engineering is a process wherein a product is studied for its components, and a product with similar composition is developed. The process was initially conceptualised for hardware products but was soon initiated in other specialities, like reverse engineering food, beverage products and pharmaceuticals. Reverse engineering has gained importance in the nutraceutical sector as well.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.