Reverse Engineering

Transforming your Vision into Reality for Product Development

Home > What We Do > Reverse Engineering

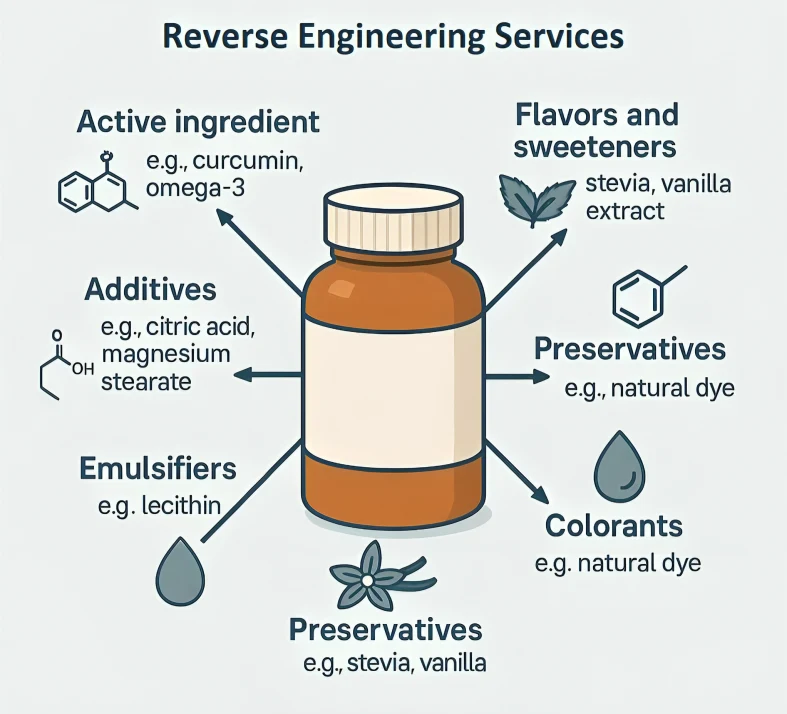

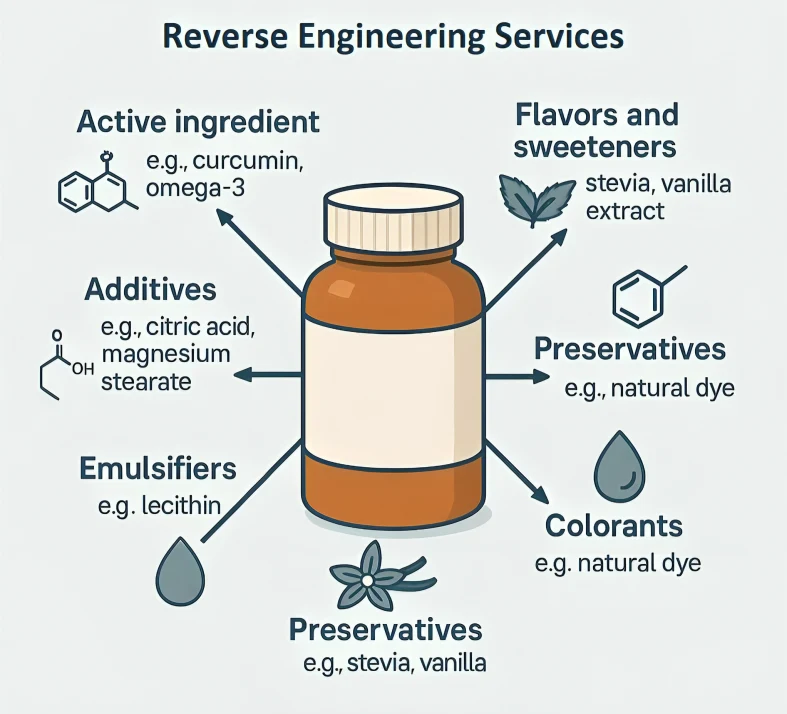

Deformulation and Reverse Engineering Service

From Benchmark to Blueprint

Reverse Engineering

Why Choose Deformulation and Reverse Engineering?

- The deformulation and reverse engineering services that we provide are to help you innovate, improve quality, and gain a competitive advantage in the food, nutraceutical, cosmetic, and pet nutrition industries. Here is what we can offer for you:

- Acquire specific detail on the formulations of competitors with reverse engineering reports for food, supplements, functional beverages, and pet nutrition products.

- Identify issues with product stability, bioavailability, and ingredient incompatibility - which can affect the performance of a product, the shelf-life of a product, or both.

- Facilitate improvements in existing products by quantitatively reverse engineering or deformulating (up to the ingredient level) products that have defects, inconsistencies, or performance deficiencies.

- Augment sourcing of raw materials and processes in manufacturing, utilizing your own knowledge of ingredients and sourcing options, while receiving data-based insights from comprehensive analytical characterization and ingredient mapping.

- Discover new ingredient synergies along with functional enhancements based on emerging consumer trends and evolving nutritional science.

- Assist you with regulatory compliance and product certification (e.g., FSSAI, FDA, EFSA, ISO) by providing solid deformulation reporting and validated analytical methods.

Our Expertise in Reverse Engineering and Deformulation

The Food Research Lab’s Contract Research, Development, and Pilot Manufacturing (CR&D), team consists of both scientific expertise and industry experience to provide you with tailor-made solutions to reverse-engineering and deformulation formulation development. We will partner with you to ensure that the development of food products is consistent with evolving consumer preferences for healthier, tastier, and sustainable foods.

Our Reverse Engineering & Deformulation Methodology

Tailored Approach Based on Product Complexity

All projects will ultimately involve different approaches due to factors including the type of product, ingredient complexity, and your project goals. Below are examples of decades-old and 21st century analytical approaches we employ for identifying and quantifying ingredients accurately for your reverse-engineering and deformulation projects:

- Physical property characteristics: e.g., texture, color, pH, water activity, rheological characteristics, etc.

- Chemical properties: Identification and quantifying analysis of all the macronutrients, micronutrients, active compounds, and additives.

- Surface and microstructure: morphology and compositional mapping for product integrity and performance.

- Performance testing: sensory analysis, shelf-life predictive analysis.

- Our instrumentation is equipped with GC-MS, HPLC, FTIR, spectrophotometer, texture analyser, etc. to provide reliable reverse engineering data and deformulation characteristics to build and optimize your product.

What We Do

Key Reverse Engineering and Deformulation Services Offered

We offer detailed deformulation services tailored for food, nutraceuticals, cosmetics, and pet nutrition products supporting research and development (R&D) application such as quality assurance, regulatory compliances and competitive benchmarking.

Prior to scale-up develop specifications and evaluate new suppliers (change of supplier), new functional excipients, or botanical extract under consideration for reformulation to ensure compatibility and regulatory safety.

Confidence in identifying and differentiating a product’s identity and quality during their Research and Development or when comparing to products intentionally or unintentionally using advanced reverse engineering approaches.

Support or refute claims like: “High Protein,” “No Added Sugar,” “Natural” or “Organic.” Provide consumers’ confidence and ensure legal compliance with accredited testing and expert review for consumer confidence or lab-based verification.

Verify that a product adheres to label claims during the product development process or third-party benchmarking. For use by investors, buyers, and R&D teams.

Identify hidden allergens, cross-contaminants, or prohibited additives using advanced analytical methodologies and techniques including LC-MS, ELISA, and FTIR. Useful for “free-from” claims, or for sensitive at-risk populations.

Assist clients to demonstrate non-infringement or originality of formulations considering reverse-engineering data and compositional support documentation.

Testing alternative ingredients, new suppliers, or sustainable substitutes prior to full scale use ensures ingredient compatibility, performance and price/value.

Create corporate food, dietary supplement or cosmetic formulations with known and/or inferred ingredient definitions, including process steps, functional additives, and sensory details.

Conduct a series of analytical evaluations to competitor products to find formulations that have changed, assess ingredient costs and sourcing if new products differ due to global supply chains creating constraints and/or opportunities.

Understand how a product is being processed – heat, mix, shear sensitivity, emulsification – so you can recreate the performance, texture and shelf stability under manufacturing protocols.

Identify macronutrient levels (protein, fat, fiber) and functional actives (curcumin, omega-3s, caffeine, flavonoids, etc.) to replicate nutrition panels or confirm dose levels in supplements and herbal remedies.

Identify excipients, additives, and enhancers in nutraceutical tablets, powders and cosmetic formulations, to ensure functional and sensory replication.

Sensory attributes (mouthfeel, viscosity, flavor, aroma, skin-feel) can be replicated, by combining analytical methods (TPA, rheology, GC-MS) such as using an expert sensory panel. Understand scope of replication first with products such as desserts, beverages, creams and spreads.

Providing technical evidence and compositional data or possible infringing parties, can help assess if an Intellectual Property infringement (or defending against) is plausible, and support decisions around commercializing or manufacturing scale-up.

Marketing claims on front-of-pack materials and search engines can be validated by analytical deformulation and benchmarking, for example looking at (validation tests as) “high protein”, “sugar free”, “natural” etc.

You may be failed or seem functionally inconsistent but likely you have an unintentional defect in your food, nutraceutical or cosmetic product. You may also have undiscovered contaminants or ingredients affecting quality attributes or performance.

Detect differences across batches of produce in relation to texture, color, composition or bioactive content to help minimize product variation and protect brand integrity.

Identify and remove directed or non-compliant ingredients (under various legislations in various jurisdictions (FSSAI, FDA, EFSA, REACH) across the use of reformulating, clean label and sustainable alternatives.

Industries where we specialize in reverse engineering and deformulation capabilities

At Food Research Lab, we offer a range of specialized product development for Contract Research & Development (CR&D) services on fee-for-service basis catering to a variety of industries. Our expertise allows us to support the development, regulatory compliance and commercialization of science-based, consumer-ready products, with specialization in the following areas:

Limitations and Challenges in Reverse Engineering and Deformulation

Services we Offer

Our Integrated Contract Research & Development (CR&D) services support full-spectrum product development from lab to launch which comprise the entire product lifecycle, from concept validation through regulatory submission and market introduction

Applications

We partner with you every step of the way to bring your product ideas to life, from early concept to getting them safely to market. Our team guides you through research, development, and regulatory processes with care and expertise. Together, we make sure your innovations reach the people who need them.

Regulatory and Ethical Considerations in Reverse Engineering

Why Partner with Food Research Lab for Reverse Engineering and Deformulation?

At Food Research Lab, we apply scientific rigor, regulatory knowledge, and full-spectrum technical delivery to every reverse engineering and deformulation project. Clients choose Food Research Lab not only because we can analyse, but we can help them turn that analysis into practical steps to implement in the lab or at the pilot-scale.

| Our Core Strengths | What It Means for You |

| Advanced Analytical Infrastructure | We have access to state-of-the-art analytical instruments (GC-MS, HPLC, FTIR, ICP-MS, etc.) which enables us to provide you with accurate quantification of ingredients, excipients, actives, and trace levels of compounds, ensuring accurate and reproducible results of reverse engineering investigations. |

| Multidisciplinary R&D Expertise | We bring together food technologists, chemists, nutritionists, and regulatory affairs scientists to provide you solutions requiring integrated action. The deliverable for you is a working deformulation strategy distinct to your product goals and challenges in the market. |

| Strict Confidentiality and IP Protection | We operate under robust NDA frameworks and data security protocols to safeguard your proprietary interests — essential for competitive and legal assurance. |

| Bench-to-Pilot Scale Execution | We bridge the gap between analysis and production by offering pilot-scale replication, stability testing, and process standardization, ensuring seamless transfer to manufacturing. |

| Deep Regulatory Understanding | Whether your target market is governed by FSSAI, FDA, EFSA, or CODEX, we will take the approach to develop a deformulation report or reformulation plan that considers the regulatory packaging environment, providing you the best opportunity to expedite certifications, audits, and execution to any global market. |

Why Choose FRL

We support start-up businesses, contract manufacturers, private-label brands, and export-oriented companies and are happy to provide tailored New Product Development services that meet scientific rigor and regulatory requirements.

Certifications (ISO, GMP, FSSAI, USFDA)

Certifications (ISO, GMP, FSSAI, USFDA)

Expertise in clean-label and functional formulations

Expertise in clean-label and functional formulations

Testing capabilities (sensory, stability, analytical)

Testing capabilities (sensory, stability, analytical)

Experience supporting startups and larger global clients

Experience supporting startups and larger global clients

Deep regulatory expertise from concept to certification

Deep regulatory expertise from concept to certification

What made to choose FRL

We help you to comply with guidelines and attain certifications that you need.

What made

Choose

FRL

Caramel

Thank you for the Update and effortd caramel. We Appreciate the detailed trials and variations you've conducted. Please Ensure the flavor alignment is testes accordingly. I look forward to the final version and appreciate your continued dedication.

Project Code:24FRL-BEV-NPD 4577-01

Name:Mohammad Hassan

Pasta

Very First thing, You all should feel proud yourself that you made something that do not exist in market. Heat and eat pasta with bold flavours.

Project Code:24-FRL-FOD-NPD-2462-02

Name:Miral

Protein Biscuits

V19 plain is the best anf finalized from our side. It is accurate in taste(plain), texture, and after tastte is also not bitter at all, He loved it as a plain flavour. V19 cardomon should add more flavour rest everything is fine.

Project Code: 24-FRL-FOD-NPD-3449-01

Name: Mehul Molir

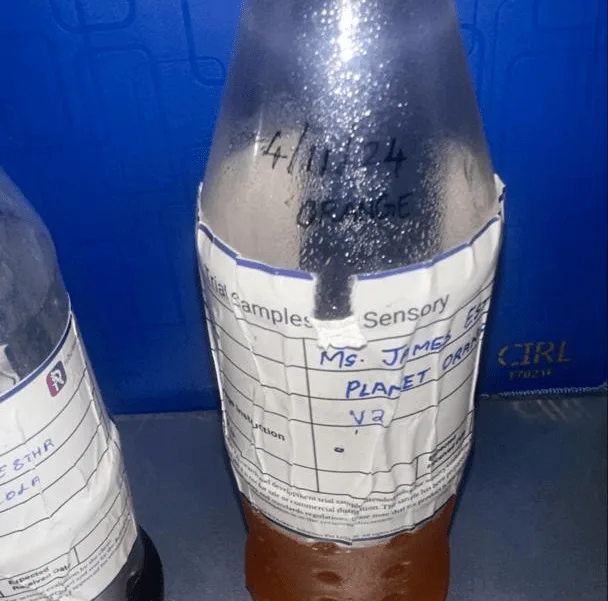

Cola

Hello, I am using the oppurtunity to appreciate the teams effort we will be picking V1 for cola, So far we don't have any complain about it, I will like to know the type of sweetner use, during the taste test some said it too sweet while some said it for orange we are picking V2, no complain too, thank you once again

Project Code: 24-FRL-BEV-REV-2878-01

Name: Esther

Energy Candy

Since a year Ago, we statrted this journey of developing energy candy and we took different steps to develop the product. I am really happy to see endless efforts you people have done to develop an energy candy, Hats off to you and your didication towards unbiased work

Project Code: 24-FRL-NPD-FTP-PMR-2660-02

Name: Harshad

Quality & Control

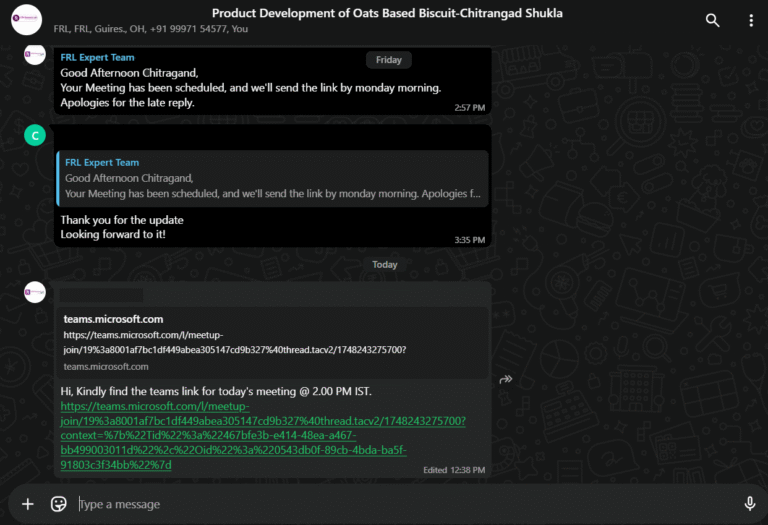

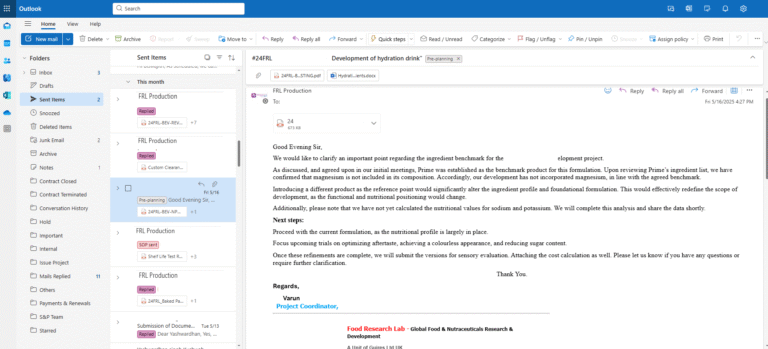

FRL prioritizes effective client communication via WhatsApp, providing timely updates and support. Additionally, we deliver detailed plagiarism reports and utilize ERP systems for robust quality control.

You might also be interested in these:

Advanced Analytical Techniques: A Comprehensive Guide for Food, Nutraceutical, and

Reverse Engineering and Deformulation: Scientific Approaches in Food and Nutraceutical

Benefits of Reverse Engineering in New Product Development

- 1

- 2

Conagra Brands Recall — Canned Meat & Poultry Products Withdrawn

Sweetrip Whitening Freckle Removal Cream Advisory (March 2025)

First Aid Beauty’s Ultra Repair Cream Recall (December 2024)

EU’s Regulation on Claims in Anti-Aging Skincare Products (2025 Update)

ASEAN Harmonization: Nutraceutical Product Registration in Southeast Asia (2025)

Optimizing Distribution Channels for the Indian Market: Key Regulations and Insights

Frequently Asked Question

New product development (NPD) typically takes between 6 to 12 months. Timelines depend on product category, the complexity of the formulation, the regulatory pathway and stability testing requirements. New Product Development includes concept development, laboratory scaling trials, stability studies and pilot scale production.

The New Product Development process includes ideation and feasibility analysis, formulation and laboratory scale trials, regulatory compliance and documentation, stability studies, sensory validation, pilot scale production, and commercialization support.

We prepare regulatory documentation, including product technical dossiers, stability data, label content, Safety Data Sheets (SDS), Certificate of Analysis (CoA), and nutritional facts for the domestic and international markets.

We can do both. We offer both new product development work, reformulation work to satisfy updated regulatory or market requirements, and reverse engineering of existing products.

We will not support the development of any alcoholic beverages, tobacco products, psycho-active substances or any product category whose actions are limited by national, or international frameworks including export permits i.e. biopharma. It’s important to us that we understand your level of transparency and ethical alignment in our partnerships.

Yes! We help as much as possible with functional ingredient selection (such as clean-label alternatives) and cost-effective sourcing that is consistent with requirements from the FSSAI, USFDA, EFSA, or an export regulatory requirement.

Yes. We will conduct both real-time stability studies and accelerated studies according to ICH, assessing and documenting physical, chemical, microbiological, and sensory stability over the shelf-life of the product.

Yes. For nutraceuticals or functional products, we can assist with scientific substantiation, literature reviews as well as partnering with a clinical research organization (CRO) if clinical studies are required.

We utilize Non-Disclosure Agreements (NDAs) with every client and have a rigorous confidentiality protocol with all staff. Any proprietary materials such as formulations and development data are always fully secured and owned by the client.

Yes. Our pilot plant can simulate the commercial production process and verifying scaling of the formulation, shelf-life and package integrity.

We assist with FSSAI licensing, USFDA registration, EFSA submission, and all other aspects of GMP, ISO 22000 and regulatory standards globally and ensuring full compliance.

Yes, we offer consumer co-creation services like focus groups, and in-lab testing with sensory panels to effective feedback for improving market readiness.

Regulatory and Ethical Considerations in Reverse Engineering

Utilize our reverse engineering, deformulation and product analysis capabilities to help you develop your product ideas into market-ready products. Need in-depth competitor analysis or creative reformulation ideas? Our team is ready to help.

More On NPD

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.