Postbiotics

Our goal is to make your dream concept a commercial product, integrating our strong knowledge of ingredients and techniques to help you make the right decisions

Our goal is to make your dream concept a commercial product, integrating our strong knowledge of ingredients and techniques to help you make the right decisions

The global postbiotics market size is expected to grow at a phenomenal rate due to the growing health awareness among consumers and couples with a high prevalence of digestive health issues. Post biotics are the heat-treated or inactivated probiotics described as waste or byproducts of fermentation and could include metabolites secreted by live bacteria or released after bacterial lysis, such as enzymes, peptides, teichoic acids, peptidoglycan-derived muropeptides, polysaccharides, cell surface proteins, organic acids and short-chain fatty acids, and proteins from beneficial microorganisms (Metabolic products from Pediococcus acidilactici, L. reuteri, E. faecium, Saccharomyces cerevisiae , L. fermentum BGHV110, B. bifidum and L. acidophilus fermentation) that confer a health benefit on the host. Postbiotics have a wide variety of applications in the food and nutraceutical industry, including sweetening agents and texture enhancement.

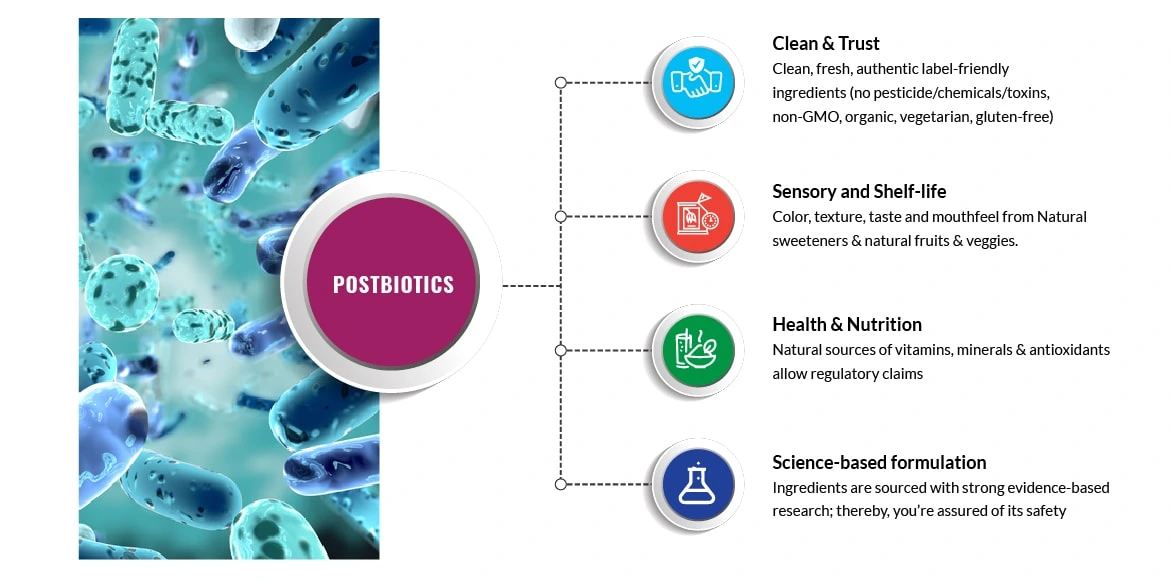

Food Research Lab, our food formulation scientists, formulate innovative prototypes of postbiotic products in the form of food, nutraceuticals and supplements in the successful manufacture of these products. We manipulate ingredients to keep the texture soft, with clean flavor and optimal viscosity. FRL’s scientific expertise partners to create winning products that meet the above requirements.

We use secreted polysaccharides, extracellular polysaccharides, cell lysates, teichoic acid, peptidoglycan-derived muropeptides and pili-type structures, which in turn, combined with nutritional components to promote health. The beneficial effect of post-biotics includes anti-inflammatory, immunomodulatory, anti-obesogenic, antihypertensive, hypocholesterolemic, anti-proliferative, and antioxidant activities. Our procurement team from FRL FRL hunt for the latest innovations to identify best practices globally to develop postbiotic products.

We develop baked goods and confectionery products, postbiotics Food & Beverages (Dairy Products, Cereals, breakfast cereals, Baked Food, Fermented Meat Products, Dry Food Postbiotics & Others), postbiotics dietary Supplements (Food Supplements, Nutritional Supplements, Specialty Nutrients), Infant Foods, Animal Feed postbiotics using the latest technology and processing method at the same time maintaining shelf life and an appealing appearance, texture and taste. We adopt both para-probiotics and FIFs, where the latter is non-viable probiotics or inactivated probiotics, while the former is an infant or follow-on formula that has been fermented with lactic acid-producing or other bacteria and, in most cases, does not contain viable bacteria.

FRL's scientists and formulation experts develop postbiotic products and supplements with varying dosages that have the capacity to modulate the sensory quality and stabilizing properties as well. Using natural ingredients or different treatment processing methods and technology.

We can formulate the products in the form of ready-to-drink, ready-to-serve, ready-to-eat, ready-to-cook, ready-to-drink, ready-to-mix protein powders, meal replacement drinks, meal kits, low carbohydrate ingredients, sports bars and formulations along with powder form, soft or hard gels, capsules, tablets, syrups, gummies, or sachets containing a concentrated source of minerals, vitamins, or botanical extracts.

FRL's scientists and formulation experts develop a highly functional strength product that provides the intended results. We adhere to the international guidelines and formulate our product to make the product high fibre, low or no sodium claim, low or no sugar claim, and low or no-fat (saturated fat), low/reduced carbohydrate claims at the same time meet the dairy-free claim as well. Our formulation experts ensure that the end product would meet the required pH, dispersibility, efficacious dosage, shelf life, glycemic index, desired satiety, mouthfeel, flavour, odor and taste. Through years of expertise and knowledge, we bring in the right solutions that fit your requirements.

Any ingredient incorporated into the formulation needs to achieve its intended function in the human body at the same time, must adhere to safety guidelines. At FRL, we substantiate this from many different types of investigation, including secondary research for existing ingredients or, if it's novel, publishing the work in reputable, peer-reviewed journals. Data for this will be derived from chemical comparisons and analysis, activities (e.g., ORAC or oxygen radical absorbance activities), testing in animal models, genomic/gene expression studies, in vitro bioassays and, most compelling of all, human clinical testing. Through years of expertise and knowledge, we bring in the right solutions that fit your requirements.

We follow quality measures to ensure the products are safe from both the supplier and the buyer's perspectives. We carry out Marker Chemistry (e.g., HPLC, GC etc.), Microbiology tests (e.g., Pseudomonas, Salmonella, Escherichia Coli), heavy metal analysis (e.g., lead, arsenic, cadmium kept below the regulatory limits), Contamination (e.g., metal flakes from machinery), physical characteristics (e.g., powders for tablets must have low moisture content) and stability (e.g., the time for a product from initial production). We use compendium methods (USP and European Pharmacopeia) for an extensive validation process.

We follow a specific set of regulations that a product must adhere to. This includes manufacturing flow chart, solvents, quantitative ingredient lists, physical characteristics, GMO status, certifications, radiations, pesticide/chemical/ residue, contaminants, microbiology, allergens, animal derivation, and safety (Standard Material Safety Data Sheet – toxicity or clinical testing). We assist ensure to clear the ingredient supplier completes clearance through the target country’s regulatory agency prior to its inclusion in formulas. Through our years of experience, our team can speed up the acceptance and inclusion of new material. Our product development team complies with the Food, Drug and Cosmetics Act (FDA 2009), DSHEA and the Fair Packaging and Labeling Act (Federal Trade Commission 2011), safety and quality food and food supplements guidelines delineated by WHO and the United Nations Food and Agricultural Organization (FAO). Our team ensures to use only acceptable ingredients that are found in the International Nomenclature. We also adhere to the local country’s guidelines as per the client’s request, such as for the Japanese Ministry of Health, Labor and Welfare (MHLW), The Chinese Health Care Association (CHCA), China’s State Food and Drug Administration (SFDA) and FSSAI.

For further information or prices please contact us: