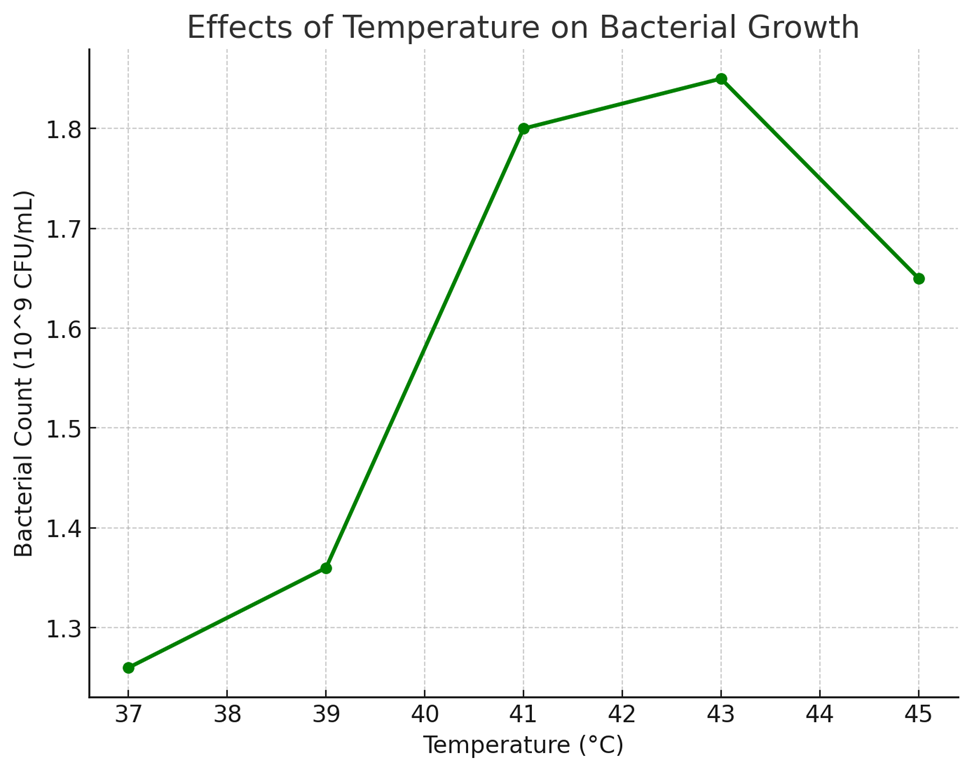

Temperature Sensitivity

Temperature plays a critical role in probiotic viability. Bacterial strains become inactive at low temperatures and may be destroyed at high temperatures. Studies show that the fermentation time to reach the required H+ ion concentration decreases as temperature increases. However, excessive heat can deactivate bacterial enzymes, reducing probiotic efficacy. For instance:

- Lactobacillus casei demonstrates optimal biomass production at temperatures of 35°C and 37°C.

- In goat yogurt, the bacterial count significantly increases over the first 3 hours of fermentation but slows over 24 hours, with peak bacterial counts observed between 39°C and 43°C. Acidity is optimal at 43°C.