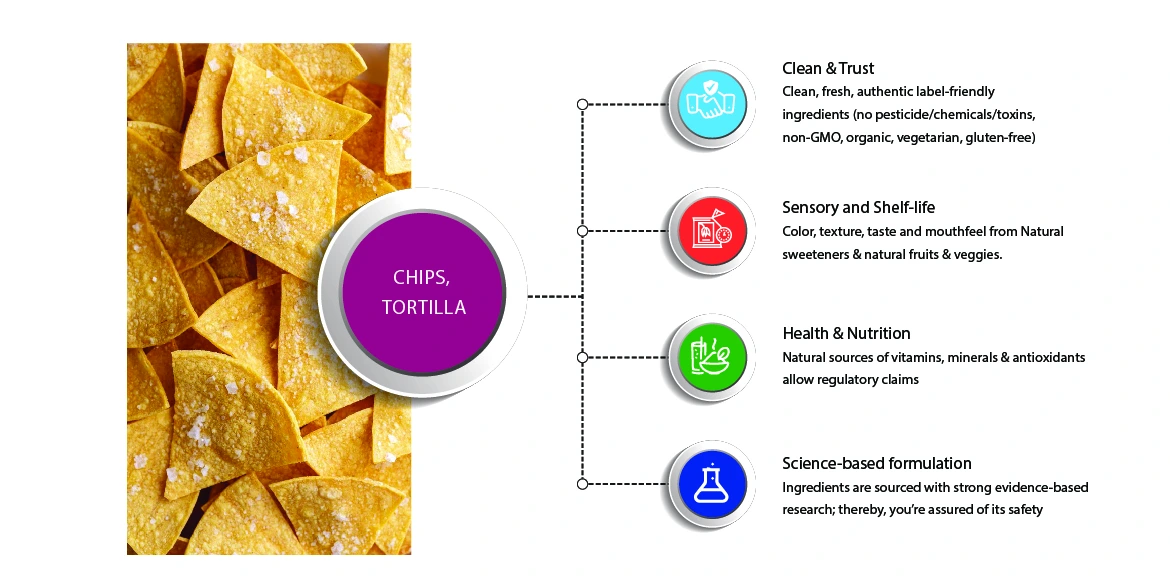

Chips, tortilla

We specialise in developing crunchy and nutritious chips and tortillas which are highly demanded by consumers

We specialise in developing crunchy and nutritious chips and tortillas which are highly demanded by consumers

Snacks are the foods that are consumed between meals, and Tortilla chips are expected to witness significant consumption in the coming years. Busy lifestyle, convenience, health conditions and urban working population are the factors contributing to the consumption of the tortillas. Food Research Laboratory supports you in the successful development of chips, the largest food sector in all markets. With our latest technology, we can help you in the development of chips, tortillas, crisps, saltines, pretzels, popcorn, extruded puffed and baked/fried products, meat snacks and rice-based snacks.

Food Research Lab's Food & Nutraceuticals Contract Research Laboratory network provides manufacturers with advanced scientific and research capabilities. Contact our scientific experts to discuss how we can help you

For further information or prices please contact us: