CLIENT

Whey protein beverage

Beverages

OUR ROLE

We redefined fast-casual loyalty

Today’s Task

What We did Today?

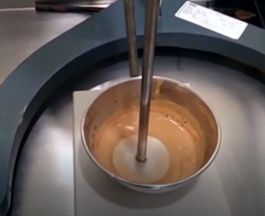

Whey protein beverage

Event: I planned to optimise the processing methods for developing whey protein beverage.

How I felt it (initially before executing the actual task): The hands-on experience of a new product formulation seems intriguing to me.

Actual Task: Product formulation

What did I learn?

A thorough research on product development was done, also giving importance to critical control points. For instance, the whey protein solution coagulates and gets fermented when the powder is added to water. Therefore, the product should be pasteurised and homogenised to prevent fermentation and extend its shelf-life. For pasteurisation, the product was heated to an optimum temperature for a stipulated time. The product was then homogenised at for a specified time, and then ultrafiltration was carried out at a desirable rate. A zero-calorie sweetener, stevia, was used, and potassium sorbate and sodium benzoate acted as preservatives.

Solution

What I did Today

Trial 1

Trial 2

Trial 3

Outcome :

The R&D contract facility had formulated ready-to-drink whey protein beverage that had an excellent sensory property.

VideoLink: https://www.youtube.com/watch?v=dFFNrEgjO-w

What went well?

The product had an excellent sensory property.

What Could I have done better?

More research is required to enhance the shelf-life of the product. Also, HTST pasteurisation should be done instead of the LTLT method to increase its sensory score. Ultrafiltration has to be done immediately.