Tapioca is a woody perennial shrub with an edible root that grows in tropical and subtropical regions, such as Asia and southern Africa. Tapioca is a starchy, granular meal made from tapioca roots that may be eaten as a vegetable, baked into bread, or used to thicken liquid dishes like puddings. Tapioca juice is a Brazilian term that means “tapioca juice.” Cassava is a staple meal for an estimated 800 million people worldwide (FAO, 2013). In 2016, global output was 277 million tons. In a recent FAO food outlook study, cassava was the sole root (FAO, 2018). Cassava root has unique features that make it a viable botanical source of starch. The root has a low protein and fat content, making its starch, often known as tapioca, easier to isolate. Tapioca is made from dried and processed cassava (manioc) root used in food, paper, and toothpaste. The Tapioca Starch is discussed in this article, as well as contemporary research trends.

Research and analysis on the global market for tapioca starch

Tapioca is a woody perennial shrub with an edible root that grows in tropical and subtropical regions, such as Asia and southern Africa. Tapioca is a starchy, granular meal made from tapioca roots that may be eaten as a vegetable, baked into bread, or used to thicken liquid dishes like puddings. Tapioca juice is a Brazilian term that means “tapioca juice.” Cassava is a staple meal for an estimated 800 million people worldwide (FAO, 2013). In 2016, global output was 277 million tons. In a recent FAO food outlook study, cassava was the sole root (FAO, 2018). Cassava root has unique features that make it a viable botanical source of starch. The root has a low protein and fat content, making its starch, often known as tapioca, easier to isolate. Tapioca is made from dried and processed cassava (manioc) root used in food, paper, and toothpaste. The Tapioca Starch is discussed in this article, as well as contemporary research trends.

Market view

According to a recent analysis, the global tapioca starch market is expected to increase at a pace of 4.8 % in value from 2019 to 2027, reaching USD 9.28 billion. In the tropics, cassava is an essential crop for food security and revenue production. With an annual production of 38.18 million tonnes, Nigeria has the highest area under cassava (22.25 %) of all cassava-growing countries worldwide. The Congo Democratic Republic is the world’s second-largest producer of cassava, accounting for 10% of global output. Brazil is the world’s third-largest country by land and the second-largest by production. India leads the world in cassava productivity, with 27.92 t/ha compared to the global average of 10.76 t/ha.

India accounts for 1.30% of the global manufacturing area. On the other hand, India is fourth in Asia and 14th in terms of space, and third in Asia and seventh globally in cassava root output. Although it is grown in 13 states across India, it is mainly grown in its southern peninsular region and the northeast to a lesser degree. Due to the ideal environment and practical usage, the crop is concentrated in Kerala, Tamil Nadu, and Andhra Pradesh.

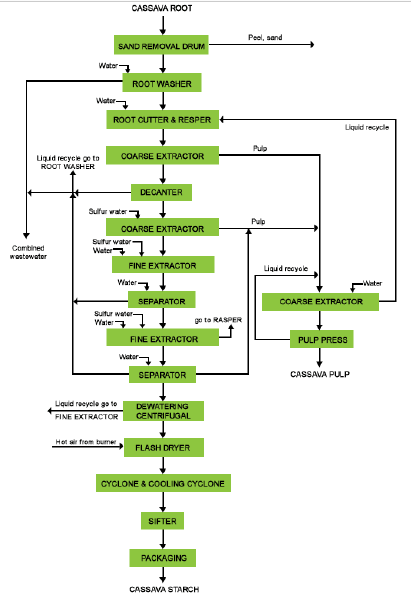

An illustration of the tapioca starch production process

Tapioca Starch

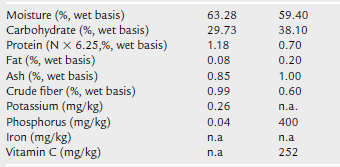

Tapioca starch comes from the cassava plant roots, which grows between the Tropics of Cancer and Capricorn in tropical climates. Cassava is called yucca in Central America, mandioca or manioca in Brazil, tapioca in India and Malaysia, and cassada or cassava (Africa and Southeast Asia). Cassava refers to the plant’s roots in North America and Europe; tapioca refers to starch and other processed goods. The plant belongs to the spurge family of plants (Euphoriaceae). Cassava was previously classified as two edible species of the genus Manihot, Manihot ultissima Phol and Manihot palmata, based on the occurrence of high and low cyanide concentration in roots (also known as “bitter” and “sweet” cassava). Manihot esculenta has just been identified as both a bitter and sweet cassava species. Typical mature roots contain 60–70% water, 30–35% carbohydrate, 12–2% fat, 12–2% fibre, and 12–2% protein, with trace amounts of vitamins and minerals.

Table 1. Cassava root proximate analysis [1]

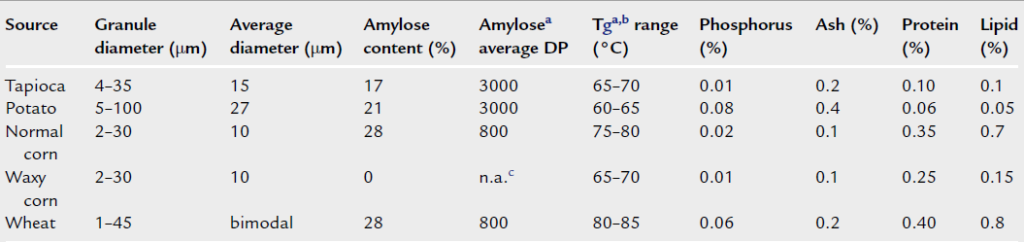

Tapioca starch is distinguished from other starches by its low residual materials (fat, protein, ash), lower amylose content than other amylose-containing starches, and high amylose and amylopectin molecular weights. Because tapioca starch contains minor phosphorus that is partially detachable, it is not bonded as the phosphate ester, as is the case with potato starch. Protein and lipid readings of zero are also relatively frequent. Tapioca starch differs from grain starches in large part because of its low protein and fat content. Cassava starch typically includes 17–20 % amylose. Unlike corn (0–70 % amylose content) and rice (0–40% amylose content), cassava starch has no substantial variation in amylose content. Like those of other starches, cassava starch’s amylose molecules aren’t unbranched, as seen by their beta-amylolysis limit, lower than maize, potato, rice, and wheat starches. Table 2 shows a comparison between tapioca starch and other starches.

Modification

Physical alterations, chemical modifications, and genetic alterations are the three types of starch alterations. Shear force, blending, and heat treatment are all used to modify cassava starch physically. Many extruded items and snacks are made using a mix of heat treatment and shear force. Alpha starch or pregelatinized starch and heat-treated starch are two well-known physically modified cassava starch products. Both native and chemically modified Tapioca starches may be easily transformed into a pregelatinized (instant) form, commonly known as cold-water-soluble starch. They were pasting the starch slurry (30–40% dry solids with or without additions), and drying results in this physical alteration. Continuously feeding starch slurry onto a heated drum at 160–170°C is the traditional preparation method. The starch is boiled and dried before being scraped from the drum and milled to the correct particle size in a single operation.

Tapioca starch may be changed by various chemical and biological processes, although the resulting compounds are more heterogeneous than those produced by other modified starches. Because it is a cost-effective approach for changing starch structure and functions, genetic modification of starches has gotten a lot of interest. Antisense suppression of granule-bound starch synthase (GBSS), the enzyme responsible for amylose production, was used to modify the cassava plant genetically. This cassava genotype provides amylose-free starch (all-amylopectin or waxy starch), desired in many applications and eliminates the need for an ecologically unfavourable chemical treatment to modify the starch extraction. This might be another important factor in propelling the cassava starch sector forward. Lipids and protein residuals are substantially lower in native starch than in many other commercial starches. Tapioca starch’s qualities have been used in various sectors. They’ve been further strengthened by physical and chemical alterations that allow for precise control of their qualities to meet the demands of clients in the process and product applications. On the other hand, Tapioca starch is recognized as a speciality starch outside of its native region.

Waxy Starch

Five novel cassava varieties containing waxy starch were discovered by the International Center for Tropical Agriculture (CIAT) in Colombia. These new species are not GMOs; they were created utilizing non-GMO plant breeding procedures. The tapioca starch produced by these new waxy species is amylose-free. Thailand was the first country to develop waxy tapioca starch and process it industrially. Waxy starches tend to expand in water than regular starches, and excessively swollen granules are more vulnerable to shear pressures.

Furthermore, when hydrated amylopectin molecules liberated from waxy starch in hot water are cooled, they do not quickly associate. The lack of amylose in waxy starches’ granules is responsible for their distinctive pasting capabilities. Amylose suppresses granule swelling in regular starches, and its linear molecules readily engage in association. When compared to their non-waxy counterparts, waxy starches produce pastes that are more stable at cold temperatures. Continued research on waxy tapioca starch to improve its pasting properties, such as eliminating the cohesive texture and increasing resistance to shear and acidic conditions during cooking while maintaining a clean label, will develop new starches with novel ones properties and applications. Tapioca starch worldwide commerce will continue to grow as the variety of qualities of tapioca starches grows. Table 3 presents the results of spontaneous mutation research on non-GM waxy tapioca starch.

Table 3. Production of waxy tapioca (cassava) starch by natural mutation [2]

| Invention/Findings | Reference |

| Waxy tapioca starch production (coded as AM206-5) by non-GM | Ceballos et al. (2007) |

| Waxy tapioca starch’s pasting and cold-storage stability compared to other botanical sources (normal/waxy genotypes, maize, potato, rice, etc.) | Sánchez et al. (2010) |

| Waxy tapioca starch production through crosses between AM 206-5 and cultivars in Thailand | Aiemnaka et al. (2012) |

| Waxy tapioca starch mutants, regular tapioca counterparts, and additional waxy starches generated from maize and potato molecular structuresThermal properties of granules, morphology | Rolland-Sabaté et al. (2012) |

| Waxy tapioca starch mutant molecular structures compared to several transgenic waxy cassava starchesGranule morphology, thermal properties | Rolland -Sabaté et al. (2013) |

| Crosses between AM206-5 and other clones resulted in increased crop production and waxy tapioca starch pasting qualities. | Karlström (2015); Karlström et al. (2016) |

| AM206-5 and wild-type samples were compared to the molecular structures of several waxy tapioca starches.Pasting properties, refrigerate/freeze-thaw stability | Morante et al. (2016) |

| Crosses between AM206-5 and other standard tapioca cultivars improved crop quality, cyanide content, and starch pasting qualities. | Rojanaridpiched et al. (2016) |

| Thermomechanical properties of AM206-5 compared to waxy maize | Pulido Díaz et al. (2017) |

Food Applications

The food business has the broadest range of tapioca starch applications. Tapioca starch has been used as a thickening and stabilizer in several food applications, focusing on its lack of taste contribution to food systems, allowing complete and instant detection of the dish’s flavour. Chemical alterations, under the US Food and Drug Administration’s widely acknowledged restrictions, have resulted in highly specialized tapioca starch products that add value and utility to meals. Thailand has rules for chemically modified starches allowed for food uses, as one of the world’s largest makers and exporters of cassava-based modified starches.

- For its physical features of texture and durability, as well as its minimal taste contribution, tapioca starch has long been the starch of choice in infant food.

- Tapioca starch will have a flavour, molecular weight, and non-starch residuals advantage over cereal starches in the quest for physical alterations that match the attributes of chemical alterations.

- In conjunction with other components, tapioca starch is widely utilized to produce Asian-style noodles.

- Tapioca starch dextrins have enabled food manufacturers to create low- or no-fat products with the flavour, mouthfeel, and texture consumers expect from the original food product. Dextrin is now used daily- and no-fat items such as meats, sauces, soups, confections, baked goods, and dairy products.

- Tapioca starch has been used in various chemical and physical changes to produce pudding goods in the pack of cook-up, instant, and frozen forms. Tapioca starch is used in such applications due to its lack of taste contribution and quick meltaway, enabling the tastes of the pudding to be unleashed.

- When cooked in a microwave oven, tapioca starch has been shown to contribute to puffing or popping.

- Sour cassava starch (Polvilho azedo in Brazil and Almidon Agrio in Colombia), a naturally fermented and sun-dried starch, is widely utilized to prepare snacks and cookies.

Conclusion

Low residuals in the starch and favourable taste qualities are widely employed in the food business, with development potential as the consumer changes toward low-fat meals, less reliance on chemical modifications, and avoidance of grain starches, all without sacrificing eating quality. Physical and chemical modifications to these starches are possible. Root production will improve if yield and maturity criteria are included in the hybrid selection and crop and soil management practices improve.

Food Research Lab is a global Contract R&D Food, Beverages & Nutraceutical Lab providing solutions to Food, Beverages and Nutraceuticals (F, B&N) industries worldwide.

FRL is the unit of Guires Group. With years of experience in research, especially in medical devices, pharmaceutical regulations, food product development, scientific publications and clinical trials, Guires Group has ventured into food research forming a separate unit under the brand name of ‘Food Research Lab’ to drive food innovations forward. Food Research Lab brings together the latest advances in food processing equipment, expert food scientists, chefs, nutritionists and partners from across the globe to help food, beverage & nutraceutical companies and entrepreneurs get their products to market quickly and effectively.

Food Research Lab makes your dream concept a commercial product, integrating our strong knowledge of ingredients and processing techniques to help you make the right decisions.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.