Processing Foods And Beverages With Nutraceutical Incorporated

Introduction

Consumer understanding of foods’ health and nutritional benefits for boosting health and inhibiting disease drives the global market for nutraceuticals and functional foods. Consumers in this era understand the inevitability of sustaining a healthy diet and lifestyle. Food and beverage processing consultants state that they want a greater variety of food and beverage choices on the market to assist them in meeting some of their health and wellness desires. As people live longer, rising healthcare expenses are putting a strain on public health funds. An older population is driving the global market for functional meals and nutraceutical goods with good spending ability. Providing a wider variety of foods that promote health and well-being to the general public is an important preventative approach for improving quality of life.

Challenges

Bringing an effective dose of nutraceuticals for a definite health benefit is a significant problem, as it affects the end product’s sensory attributes. Other difficulties include the need to

- avoid negative interactions between the nutraceutical and food matrix constituents and the environment using suitable food processing methods

- Minimize the nutraceutical degradation when incorporated under food processing conditions,

- stabilize the nutraceutical during the shelf life of the finished product, and

- Ensure that the food containing the nutraceutical provides the intended health benefit after ingestion.

Because many bioactive are unstable after being taken out from their natural food source, the nutraceutical may need to be encapsulated to create more stable ingredient formats before producing designed functional meals. Creating an encapsulating system for an unstable component must consider the substance’s compatibility for end-use in food and the desired health consequence.

Microencapsulated systems

Nutraceutical product consultants can encapsulate nutraceuticals and make the microencapsulated element using one or more encapsulant resources. Nutraceutical delivery structures can be built employing food-grade materials and ingredients in various ways. Emulsion-based delivery approaches (primary, double, & multilayered emulsions), inclusion complexes, liposomes, glassy matrices, biopolymer gels, lipospheres, complex coacervates and beadlets are examples.

The chosen nutraceutical may be stabilized and protected from the external environment by the matrix material or encapsulant in all of these systems until a stimulus triggers its discharge. Drying (e.g., spray drying, freeze-drying), emulsification (e.g., homogenization, microfluidization, membrane emulsification), complexation, extrusion, coating, gel network formation, layer-by-layer depositions, coacervation, and supercritical antisolvent precipitation are some of the technologies that can be castoff to make the encapsulated ingredients.

Omega 3 fatty acids

Omega-3 fatty acids have generated curiosity due to their abundant health benefits. Their health advantages are amended cardiovascular and brain health and protection against various inflammatory disorders. Omega-3 fatty acid oils, particularly (LCPUFAs) long-chain polyunsaturated fatty acids eicosapentaenoic acid and docosahexaenoic acid, are susceptible to oxidation. The development of unpleasant scents and flavours is caused by inadequate protection of omega-3 fatty acids from oxygen. Antioxidants can be added to bulk oils to prevent oxidation. Antioxidants have been employed to maintain high-quality fish oils and deliver low quantities of omega-3 LCPUFAs in some short-shelf products. Microencapsulation of omega-3 fats, as an alternative, enhances their resistance to oxidation in both the ingredient form and the final food product, letting omega-3 LCPUFAs be included in a broader range of foods.

Fat-Soluble Bioactives

Numerous other dietary bioactive lipids, such as phytosterol, phytostanol, fat-soluble vitamins (A, D, E, and K), and carotenoids, may be added to make functional meals to omega-3 fatty acids, which have garnered substantial research over the last two decades. These dietary lipids’ low water solubility and oxidation susceptibility are chief barriers to their assimilation. Because of their limited water solubility, they have a low bioavailability. Using various encapsulation technologies (emulsions, microemulsions, nanoemulsions, solid lipid nanoparticles, and liposomes) to productively incorporate these lipids and fat-soluble bioactive into functional meals, potentially enhancing their bioavailability.

Probiotics

Food and beverage processing consultants state that the food sector is very absorbed in including live probiotics in foods. They provide various health benefits but are most known for improving digestive health. Probiotics have been delivered via food, particularly dairy-based beverages, yoghurts, and cheese. Chocolate, mayonnaise, pork products, orange juice, nutrient bars, and ice cream are just a few foods that comprise encapsulated probiotics. Probiotics have difficulty surviving in low-pH liquids; however, when probiotics were encapsulated in whey protein matrices and then sprayed dried, they could stay at low pH. The capacity of the whey protein to generate a colloidal matrix that isolated the probiotics from the low pH environment compliments the probiotics’ protection.

Peptides

Bioactive peptides serve a variety of purposes. Bioactive milk peptides are among the most researched, with immunomodulatory and antihypertensive opioid properties and the ability to improve mineral absorption. Bioactive peptides derived from diverse parent proteins (e.g., milk proteins, soy proteins) are described as functional food additives. To correctly incorporate peptides into food, it is frequently required to hide their bitter taste and solve hygroscopicity difficulties by employing appropriate encapsulation techniques for their administration. The bitterness of a casein hydrolysate is reduced by complex coacervation with soybean protein isolate and pectin, and the encapsulated casein is less hygroscopic than the free hydrolysate.

Food Research Lab’s Functional Foods And Nutraceutical Product Development.

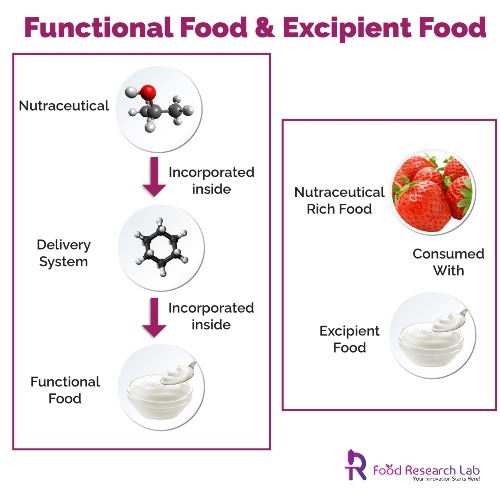

A widely adopted strategy by Food Research Lab is an encapsulation of a nutraceutical ingredient before adding it to food. Our formulation experts use it to overcome the challenges encountered when adding nutraceutical ingredients at an effective dosage without affecting the food’s sensory properties and storage stability. Different encapsulation technologies are available, and the choice depends on the properties of the nutraceutical ingredient and the target application. Using food as a carrier for nutraceutical products involves new formulation strategies and product development. Regardless of the method applied, we study the interaction between the nutraceutical ingredient and the different components of the food matrix during processing. These interactions can influence the bioavailability and bio efficacy of the added nutraceutical ingredient.

Many clients have provided our functional food processing consultants with projects where we must understand the interaction of nutraceuticals with complex food matrices, substantiate the potential health benefits of nutraceuticals added to food, and comprehend the complexities of passage from the gut into the body and how the encapsulant may influence this process. Our functional foods and nutraceutical product development service help you address all these aspects and develop a new nutraceutical product.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.