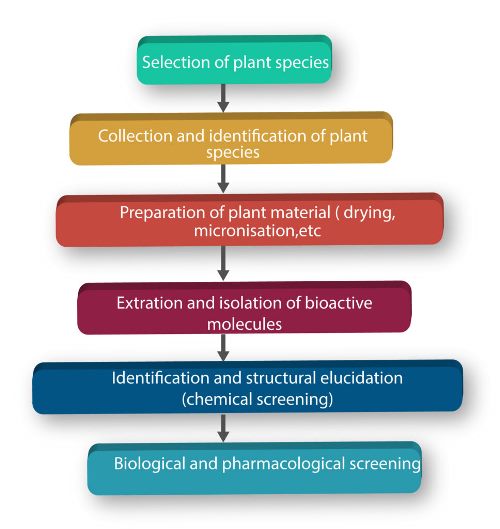

Bioactive components are compounds extracted from plants that have pharmacological effects on human health. In a way, the extracts are nothing but nutraceuticals or elements from a natural plant source extracted to create a cure for an existing disease or as a preventive measure in terms of energy enhancing, anti-ageing, health protective, general well-being properties and relaxing products. These functional foods usually required for the human’s healthy survival to treat or prevent disorders with various bioactive functions (e.g. hypocholesteremia, immunomodulators, antimicrobials, antioxidants) due to incorporation of functional enzymes such as fibers, phytosterols, peptides, proteins, isoflavones, probiotics, and prebiotics. For example, the grape used for winemaking has by-products like pomace, stems and leaves. The grape pomace has polyphenols and other small phenolic compounds exhibiting high health beneficial properties, such as cardio-protective, neuro-protective, anti-inflammatory, anti-carcinogenic, and antimicrobial activities. Other examples of fruit by-products are apple pomace, citrus peels, seeds and pulp and waste from carrot, potato and tomato. Both traditional and contemporary techniques extract them. Examples of bioactive compounds are carotenoids, flavonoids, carnitine, choline, coenzyme Q, dithiolthiones, phytosterols, phytoestrogens, glucosinolates, polyphenols, and taurine. Currently it is estimated that more than 80% of food active compounds and 30% of drugs are produced from bioactive natural compounds. In general, bioactive compounds are extracted from the strategies which is shown below.

New Product formulation using active ingredients

Introduction

Bioactive components are compounds extracted from plants that have pharmacological effects on human health. In a way, the extracts are nothing but nutraceuticals or elements from a natural plant source extracted to create a cure for an existing disease or as a preventive measure in terms of energy enhancing, anti-ageing, health protective, general well-being properties and relaxing products. These functional foods usually required for the human’s healthy survival to treat or prevent disorders with various bioactive functions (e.g. hypocholesteremia, immunomodulators, antimicrobials, antioxidants) due to incorporation of functional enzymes such as fibers, phytosterols, peptides, proteins, isoflavones, probiotics, and prebiotics. For example, the grape used for winemaking has by-products like pomace, stems and leaves. The grape pomace has polyphenols and other small phenolic compounds exhibiting high health beneficial properties, such as cardio-protective, neuro-protective, anti-inflammatory, anti-carcinogenic, and antimicrobial activities. Other examples of fruit by-products are apple pomace, citrus peels, seeds and pulp and waste from carrot, potato and tomato. Both traditional and contemporary techniques extract them. Examples of bioactive compounds are carotenoids, flavonoids, carnitine, choline, coenzyme Q, dithiolthiones, phytosterols, phytoestrogens, glucosinolates, polyphenols, and taurine. Currently it is estimated that more than 80% of food active compounds and 30% of drugs are produced from bioactive natural compounds. In general, bioactive compounds are extracted from the strategies which is shown below.

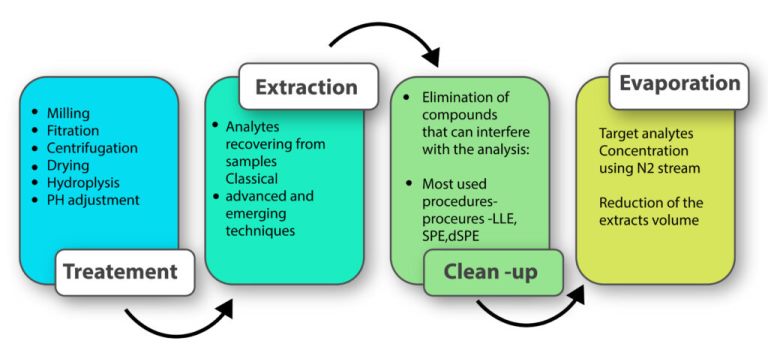

Figure 1. Strategies usually followed for the treatment and extraction of bioactive compounds from food matrices. Legend: dSPE—dispersive solid-phase extraction; LLE—liquid-liquid extraction; SPE—solid-phase extraction. (2)

Conventional Extraction Techniques

- Soxhlet: As the name suggests, the Soxhlet apparatus uses a solvent that passes through a small sample. This process is both time taking and consumes a lot of solvents.

- Maceration: A small sample is ground to a fine powder, combined with the solvent, and continuously stirred. The extract is made more efficient by diffusion and the fact that the sample’s surface is increased with maceration or grinding, thus making it easier to mix with the solvent.

iii. Hydrodistillation: Hydrodistillation undergoes three physicochemical processes, namely hydro diffusion, hydrolysis, and decomposition by heat. This process takes 6 to 8 hrs. to complete and does not involve the use of organic solvents. Distilled water is used to perform the process and is used to extract the volatile fraction in foods. The use of high temperature during extraction can often lead to the degradation of these compounds. This is one of the limitations of this technique. Hydrodistillation is a complete process. Both volatile organic compounds and non-volatile organic compounds can be extracted and physically separated in one step. Azeotropic distillation is used to separate the volatile organic compounds from the matrix. They are then condensed, collected, and separated in a Florentine flask. The soluble non-volatile organic compounds are extracted in boiling water. There is, of course, high levels of energy consumption and it is time-consuming. (3)

FLOW CHART:

There is always a risk involved about the toxicity of the solvents used to extract the bioactive compounds and the chances of presence of the same in the extracts along with low yield when the conventional methods are used. In such a case, the modern process comes handy. It works towards preserving nature. (4)

Modern techniques or green techniques are also known as cold extraction techniques. It promotes the idea of reducing the waiting time and use of resources to get the desired results with maximum efficiency. The benefits of green technologies over the conventional methods are as follows:

- faster extraction rate

- more effective energy use

- increased mass and heat transfer

- reduced equipment size

- and reduction in the number of processing steps.

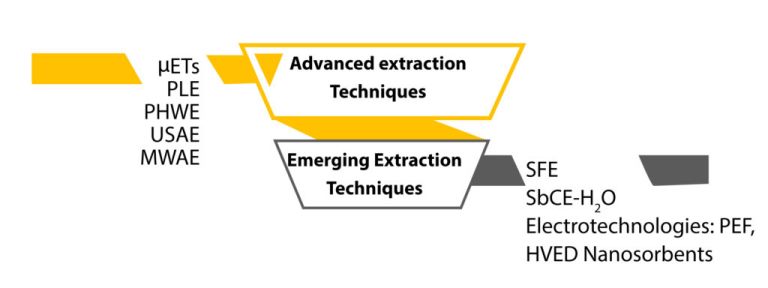

Figure 3. Advanced and emerging extraction techniques used in food analysis. Legend: HVED—high voltage electric discharge; MAE—microwave-assisted extraction; PEF—pulsed electric fields; PHWE—pressurized hot water extraction; PLE—pressurized liquid extraction; UAE—ultrasound-assisted extraction; SbCE—Subcritical extraction; SFE—supercritical fluid extraction; µETs—microextraction techniques.[1]

GREEN Techniques

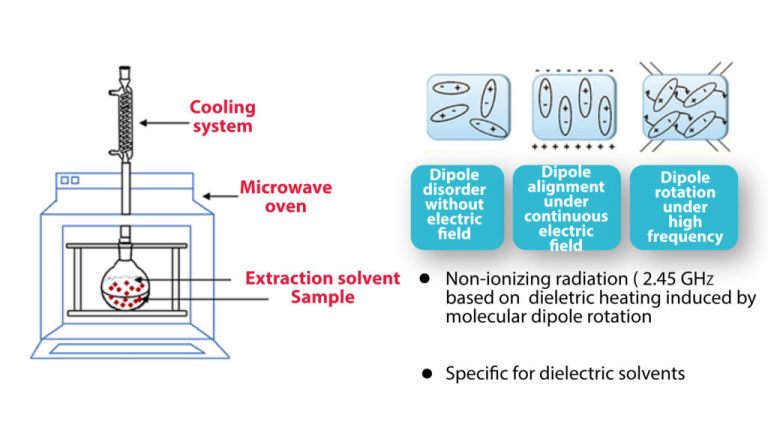

- Microwave-Assisted Extraction (MAE): MAE is based on the principle of dielectric heating. That is the process in which microwave electromagnetic radiation heats a dielectric material by molecular dipole rotation of the polar components present in the matrix. (5)

2. Ultrasound-Assisted Extraction (UAE): Ultrasound with the frequency of 20kHz to 100MHz is passed through the sample resulting in compression and expansion cycles creating cavities. These cavities collide with each other resulting in inter-particle collision, inter-particle diffusion and enhanced diffusion of the extractable compounds into the solvent. (6)

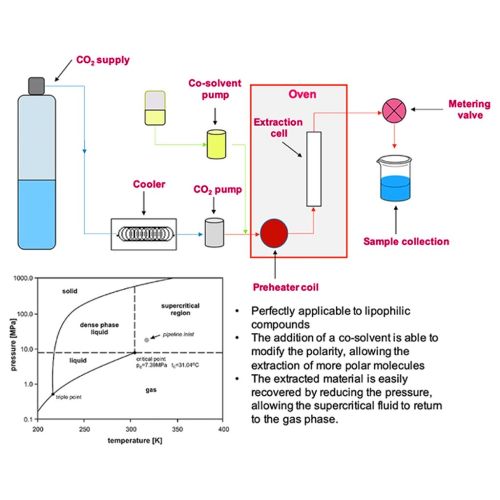

3. Supercritical Fluid Extraction (SFE): This process uses supercritical CO2. It allows selective extraction of phenolic compounds that are soluble in supercritical CO2. In comparison to the conventSupercritical Fluid Extraction (SFE): This process uses supercritical CO2. It allows selective extraction of phenolic compounds that are soluble in supercritical CO2. In comparison to the conventional techniques there are the advantages of easy recovery, selectivity, compounds stability, time, and an overall total energy saving. The physico-chemical parameters of sCO2. are temperature, pressure, and amount of co-solvent and the biomass nature and processing before extraction (lyophilization, micronization, etc.) deeply affect the final extraction yields and composition.

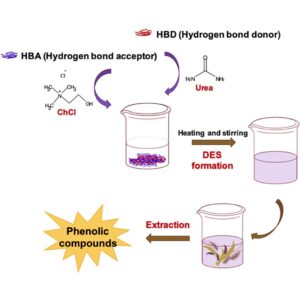

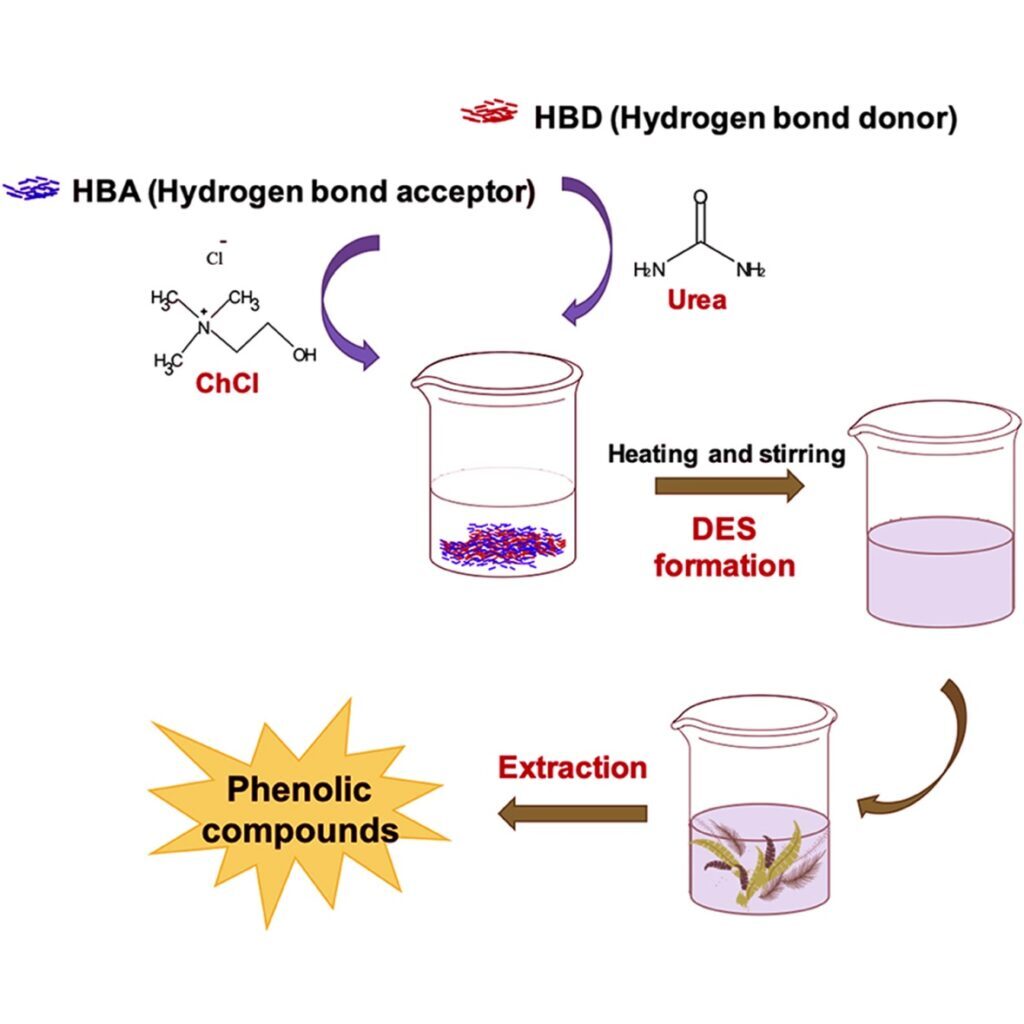

4. Deep Eutectic Solvent (DES) Extraction: The phenolic compounds from agri-food wastes are extracted using DES. DES preparation is done by mixing, at a suitable temperature, a hydrogen bond acceptor (HBA) and a hydrogen bond donor (HBD). Compared to common organic solvents, DES offer many advantages such as low price, easy preparation, and easy availability. Moreover, most of them are biodegradable with very low toxicity. (7)

Other microencapsulation techniques such as coacervation, liposome entrapment, extrusion, spray cooling, freeze drying, spray drying, co-crystallization, emulsion also been used in the food industry as a promise for functional bioactive compounds.

Food Research Lab can help you solve these problems with related to extraction of bioactive components from residual food sources, or from whole foods which can be used as food stuffs, nutritional supplements, fermented foods which are able to retain original nutritional ingredients. FRL is for food and nutraceutical manufacturers as well as those companies involved in NPD and developing spec without manufacturing. FRL gives you the ability to improve all phases and aspects of new product development, such as original specification, ideation, shelf-life, packaging. Additionally, you can get them out to market quicker than ever before.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.