The opposition among eateries is wild, and you’ll have to give your everything to be productive. We’re encouraging you out with 26 café advertising thoughts and procedures that guarantee to assist you with improving your business and get consideration from snarling stomachs all over! Also, food research lab gives you the common mistakes takes place in restaurant marketing for New product development in food industries.

What are the major problems in food formulation to make healthy food in the Food Production industries?

In Brief:

- The design of several food products concentrations on the identification of the structure and alignment of food ingredients that have the desired features

- Food research lab helps you to recognize the various challenges in the food formulation for Food product development in industries

- A thorough accepting of the functions and properties of the various ingredients is the primary challenge of food formulation problem.

Introduction

The formulation is a fundamental advance in any item improvement, be that as it may, it is a mind-boggling measure and formulators face a lot of difficulties when building up a formula. They need to contemplate different prerequisites from various groups, from showcasing, quality to administrative issues. It is additionally urgent to remain in front of the quickly advancing interest for new items and the arising patterns in food industries development. The steady requirements likewise test formulators for growth and economic assembling.

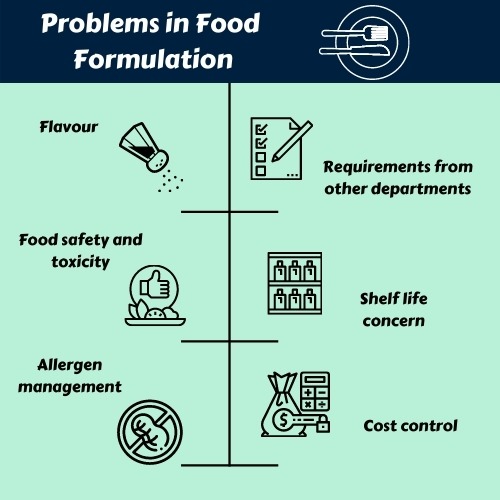

Food Formulation issues:

Cost control

Cost is a significant factor in item advancement, from the price of a new recipe in food industries to the assembling costs. It is essential to build up an item which follows specific necessities, particularly in term of estimating. Frequently, the promoting Division will build up a particular value that customers are happy to pay for an item, which, like this, will decide the highest assembling cost of food development recipes. It very well may be trying to ascertain direct material expenses if there is no appropriate cycle set up to have all data promptly accessible. Then again, it is additionally an issue when there is an excessive number of various processes and programming executed, particularly as these frameworks are as a rule from multiple suppliers and facilitated on various stages. So it gets relentless and delayed to get the necessary data from recipe development consultant. In any case, recovering data is, at that point, tedious and complicated. Be that as it may since food and drink producers work on dainty edges, controlling expenses is basic. (1)

Allergens management

Formulators should be cautious while making new Formulations or items. There are two principle parts about allergens the board. Right off the bat, they need to follow explicit prerequisites which characterize the allergens restricted, for example, if the item should be without dairy or sans nut. Then again, if there is no particular prerequisite, it is as yet essential to precisely decide and proclaim the allergens present in the result of food industrial development. Food and refreshment makers must actualize cycles to control and deal with a wide range of allergens in their items. Formulators likewise need to approach a precise information base with all crude materials data; this will assist them with figuring out which fixings to use in a formula to evade specific allergens using food development from technology.

Food and refreshment definition turns out to be significantly more confounded when formulators need to think about a few prerequisites. Those prerequisites can differ from claims that the showcasing group requires to use on the bundling, rundown of allergens that explicitly reject an item, to all the nation explicit guidelines an item should follow. Plainly the R&D group would then be able to be handily overpowered by every one of these prerequisites and struggle precisely and effectively following them.

Flavor

Beginning flavor in particular from flavor changes over the long haul, which might be a measurement of bioactive debasement or connection with different fixings. Adjusting the flavor framework and recognizing viable flavors are bioactive and item explicit cycles. It is, for the most part, helpful to look past essential flavours and advance the whole framework, including sugars and acids. Also, directed concealing frameworks are offered by a few producers for explicit bioactive mixes, just as for essential negative flavor ascribes, for example, severe, metallic, acrid, and so forth. Preferably, the testing of flavor improvement should combine with shel flife testing to comprehend and foresee long haul corruption versus inherent corruption in-measure, to create focused on covering frameworks ideally.

Food safety and Toxicity

Numerous mixes corrupt into harmful structures after some time or because of handling and collaborate negatively with other fixing parts to create deadly combinations. Furthermore, measurement control is necessary for some, bioactive mixes, including regularly utilized nutrients/minerals, for example, nutrient D and selenium. FDA has set up stronghold limits for specific fixings, and these can be set up in the Code of Federal Regulations. Note that where harmfulness considers exist, essential model frameworks or explicit grids may have been making use of which are not delegate of the particular food item or cycle of interest. Bioactive makers should make data and references to makers accessible, yet once more, assessment in the eventual outcome or potentially measure is basic. (2)

Shelflife Concerns

Numerous bioactive fixings are inclined to debasement or potentially can communicate with different parts in the food grid, bringing about loss of value or health benefit. How the fixing is delivered and put away has a significant effect on its shelflife. Contingent on explicit completed item guarantees, the bioactive should be available in the level resolved to give security adequacy toward the finish of shelflife. It may prompt overages or expansion of bioactive in the abundance of various groups. The kind of food lattice, fixing associations, preparing, capacity/taking care of, conveyance frameworks, blending and appropriation, the presence/nonattendance of cell reinforcements, water movement, pH, dampness and chelating specialists may all affect bioactive shelflife. Bioactive fixings in nourishments should remain completely useful; however, long vital and, consequently, should be moved and released fittingly to have the ideal healthful impact. Conveyance and controlled delivery frameworks are a primary method to accomplish these points. It might be superior through microencapsulation or use of other exemplification/dividing/bundling innovations.

Furthermore, strength might undercut by the response of a bioactive with different fixings or untimely delivery and presentation to stomach acids. For instance, direct expansion of iron may diminish bioavailability through collaboration with tannins, phytates and polyphenols; free iron catalyzes lipid oxidation. Bioactives should be put away under suitable conditions, preceding consolidation into nourishments, and should cut off from conditions that advance corruption or bothersome communications with light, dampness, warmth or oxygen. Delivery and appropriation conditions and dealing with necessities are likewise significant contemplations, especially as identified with temperature and moistness.

We have the experience, knowledge and ingredients portfolio to help you develop

Interested in learn more? Get in touch, we’d love to discuss your next project with you

Conclusion

Food research lab helps you to recognize the significant problems in food formulation in the food development industries.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.