Shelf life is defined as the time of storage that a product remains safe to consume and retains its desired properties such as sensory, functional, chemical and microbiological properties. Customers no longer rely on the traditional methods to dictate how to store them and have to solely depend on the manufacturer’s instruction. Whether Food Standards Code (FSC) from Australia or the UK or India, it has been generally stated that “the Standard requires packaged food, to be the date marked, and prohibits the sale of packaged food after the expiration of the use-by date” (1). Consumers often substitute one word for another, which is not accurate.

Significance of Shelf Life in Food Development

Shelf life is defined as the time of storage that a product remains safe to consume and retains its desired properties such as sensory, functional, chemical and microbiological properties.

Customers no longer rely on the traditional methods to dictate how to store them and have to solely depend on the manufacturer’s instruction. Whether Food Standards Code (FSC) from Australia or the UK or India, it has been generally stated that “the Standard requires packaged food, to be the date marked, and prohibits the sale of packaged food after the expiration of the use-by date” (1). Consumers often substitute one word for another, which is not accurate.

Understated hygienic storage conditions, use-by date implies that the intact package of food should not be consumed after the mentioned date for health and safety reasons. On the other hand, the best before day implies the food product may start to deteriorate, such as loss of functionality, texture, color, taste or may develop an odor, after the mentioned date. This will, in turn, reduce the overall consumer acceptance and likability but may not have any health implications.

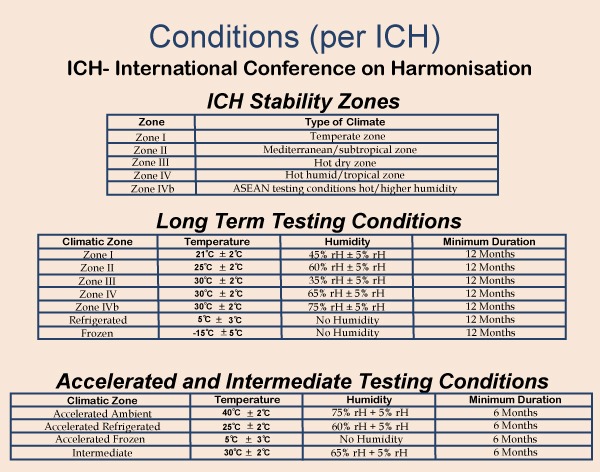

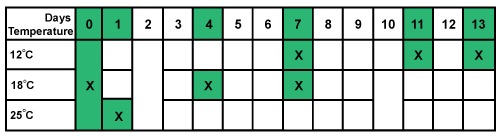

Establishment of printed expiry dates on products, the safety, quality of the food product is measured and assessed based on the shelf-life analysis. The food manufacturer or food scientists is responsible for determining the shelf life of food when developing a .The manufacturer should have extensive product knowledge to determine the various factors, such as formulation, packaging, storage conditions and distribution characteristics, that will influence the overall shelf life. The most effective way to ensure food safety is to meet the internationally recognized protocols such as Hazard Analysis and Critical Control Points (HACCP) system, adopted by the Codex Alimentarius Commission, under realistic, defined conditions (2). However, most manufacturers are reluctant to try conventional methods (such as direct methods) as they want to market the product at the earliest. Accelerated shelf-life tests are usually carried out to minimize costs using higher than normal temperatures and statistical models such as predictive models (3) by deliberately increasing the rate of deterioration. Besides, variables on the growth of spoilage and pathogenic organisms should also be considered. Direct methods are good for products with shorter shelf lives while indirect method for products with longer shelf lives especially for shelf-life claim. Figure 1a below shows the conditions as per International Conference on Harmonisation (ICH) and (b) sampling plan of the shelf life study.

What is accelerated Shelf life?

Accelerated shelf-life tests are usually carried out to minimize costs using higher than normal temperatures and statistical models.

Figure 1a. Conditions as per ICH

Figure 1a. Conditions as per ICH

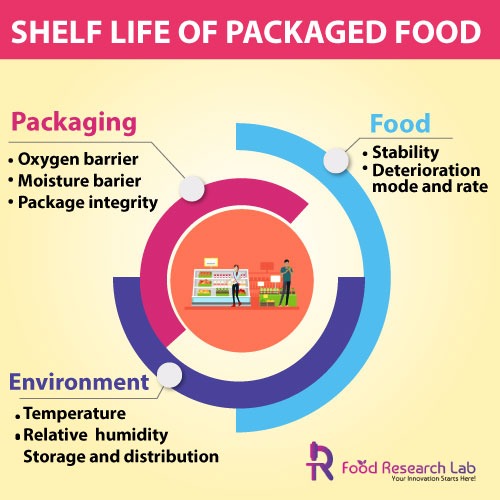

Key factors affecting the shelf life of food product

Processing & Microbiological:

The type of food processing, such as pasteurization, Ultra High Temperature (UHT), High-Pressure Processing (HPP) or freezing, can add or reduce the shelf life of the product (4). A commercially sterilized food product with proper packaging’s, such as packaged drink or canned foods, quick-frozen berries, will reduce microbial load and limit further growth. Few other key factors considered include:

- Intrinsic properties, such as pH, water activity, presence of preservatives

- Extrinsic properties, such as temperature, humidity and atmospheric pressure

Water activity (aw):

Aw is a critical factor that governs if an organism will grow in food, as most foods are delicate to lose or gain of water. This is, in turn, controlled by the type of packaging used by the food manufacturer (5). Biscuits, cookies or even savouries snacks suffer loss in quality due to moisture gain. on the contrary, baked foods as cakes may suffer from extensive dryness.

Another great example is milk, which has a shorter shelf life than pasta (more shelf-stable) due to its low water activity.

Biochemical:

Most food products undergo possible reactions which may not be beneficial or attractive to the consumer. The important reactions to look out for are oxidation, non-enzymatic browning etc. For instance, oxidation of fats and oils leads to rancidity and the development of off-flavour. This predominantly limits the shelf life of products containing fats and oils at ambient temperatures, such as potato crisps, savoury snacks, biscuits and cookies. Although freezing arrests microbial and water activity, frozen food can also have its shelf life limited by fat oxidation, for instance, fish and meats.

Food packaging and their interaction:

Most of the food products depend on the particular packaging (material) to achieve or maintain their expected shelf life (6,7). For instance, potato chips are packed under a modified atmosphere normally achieves only six weeks of shelf life. However, if the manufacturer chooses to pack the same potato crisps in plastic with less-barrier properties, it may achieve a six-month shelf life. Canned foods are processed in lacquered cans which minimizes the possibility of tin dissolution into the food. The maximum tin content requirement by Food Standards is 250 mg/Kg. A novel food packaging currently uses active packaging materials (pads and sachets placed inside of packages). Active packaging possesses active ingredients or using active functional polymers to inhibit spoilage or pathogenic microorganisms (8).

Transportation and storage:

The environment that a food product is exposed to plays a key role in shelf life. Transporting foods outside of prescribed temperatures may result in food spoilage, oxidation, and other unfavourable outcomes (9,10). Potentially hazardous foods should be stored under 4°C throughout their life. Variances in storage temperature between 0°C and 4°C in the refrigerator, exposure to sunlight, might result in loss of shelf life, activation of chemical reactions and microbial activity. Therefore, the date marked on the product will no longer be valid and true.

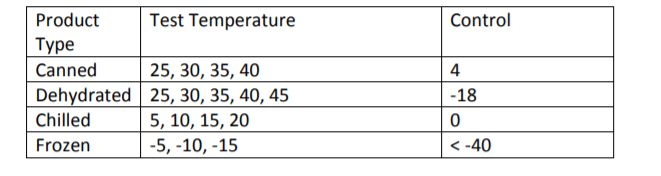

The following Table offers some recommendations of typical storage temperature.

Table 1. Most commonly used storage temperature

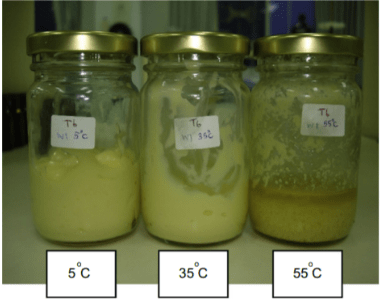

Figure 4 Mayonnaise appearance after storage at different temperatures. (11)

We have the experience, knowledge and ingredients portfolio to help you develop

Interested in learn more? Get in touch, we’d love to discuss your next project with you

About Food Research Lab

With many years of passion and experience in the food and beverage development industry, Food Research Lab serves as a one-stop solution for all your food business needs, from designing your new product, shelf life analyses, or testing or to enhance an existing one. Our food technology experts will help you through a plethora of rules and regulations across the globe to enable your product (food & nutraceuticals/supplements) to reach customers hands promptly. By working directly with us, you’re assured of getting a dynamic, innovative product of your specifications. We will also help you with a cost analysis of a new food product development for the specification and certification process of your product. Reach us at salessupport@foodresearchlab.com

Dr Raj is a trained food scientist from New Zealand with 10 years of experience. Upon completion of his PhD, he worked for various FMCGs. He is the recipient of the Oxoid food science award from the Heriot-Watt University and Callaghan grant from the University of Otago and Callaghan Innovations for his academic performance. Raj writes early in the morning, then spends the rest of the day working as a full-time technologist and as a consultant at Food Research Lab, Chennai & the UK, where he makes his experiments work.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.