The elevated level issues confronting food and drink makers today may feel like similar difficulties the business has been managing for quite a long time. Yet, the setting wherein these difficulties have changed significantly. Buyer interest for more noteworthy item development and openness, always expanding the quality and consistency pressures, more consolidated net revenues, new channel openings, and a robust labour force are only a portion of the elements. That are moving business sector elements to where food and refreshment producers need to adopt a new strategy to how they work together in food industries development.

What are the challenges faced in the Food Manufacturing Industries during Production?

In Brief:

- In an increasingly inexpensive landscape, food product companies involved in new product development and food manufacture are facing more and more challenges.

- The food product companies as an entire are preparing for a challenging year for New product development in food industries.

- Food research lab explains the problems in food manufacturing industries in this blog

Introduction

The elevated level issues confronting food and drink makers today may feel like similar difficulties the business has been managing for quite a long time. Yet, the setting wherein these difficulties have changed significantly. Buyer interest for more noteworthy item development and openness, always expanding the quality and consistency pressures, more consolidated net revenues, new channel openings, and a robust labour force are only a portion of the elements. That are moving business sector elements to where food and refreshment producers need to adopt a new strategy to how they work together in food industries development.

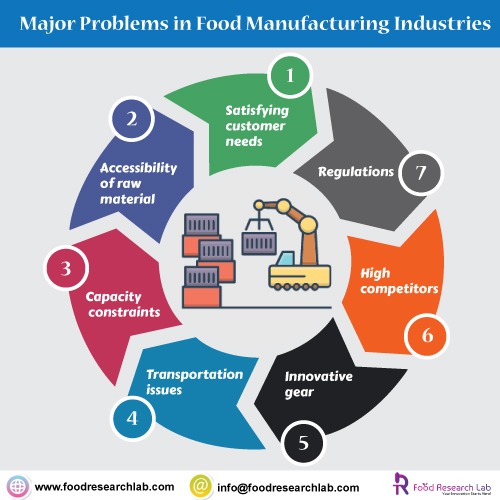

Major Problems In Food Manufacturing Industries

1. Satisfying Consumer NeedsA large number of difficulties looked by food producers identify with satisfying changing customer needs. Regularly these requirements to happen rapidly and with costs kept to a base for technological growth in food industries. Purchasers change their conduct frequently, with new inclinations and arising trends overwhelming many purchasing choices. It happens regularly, implying that food makers should create items to satisfy these needs in ever-more limited periods. Late patterns incorporate high protein items, Omega 3 enhancements, in a hurry wholesome snacks over more traditional dinners, just in a general host of other food patterns. There is no uncertainty that we have moved into a universe of more different purchaser needs where prerequisites are getting progressively close to home. Food producers need to work all the more intimately with clients to comprehend their necessities and objectives. They additionally should be as effective with regards to growing new plans and getting items out to showcase in technological food development.

2. Accessibility of raw materials

Farming produce is a significant factor for continuing food handling exercises. Because of occasional accessibility of specific yields, the area faces delays underway bringing about low inventory. For oil production, most of the oilseed makers are little and negligible ranchers with helpless admittance to asset bases, for example, composts, fertilizer, and so forth Thus, oilseeds developed by such ranchers have a low yield. Rabi crops like wheat, grain and mustard are planted around mid-November and reaped in April or May. These food grains are subject to powers of nature, which are relatively unusual. Occasional shortage and significant expense of crude materials comprise one of the essential requirements influencing the development of little scope food handling endeavours. This situation brings about the need and higher estimating of oil materials for technological market development. (1)

3. Capacity Constraints

A large number of these lack or shortage issues can be tackled by following legitimate stockpiling standards for crude materials. In any case, this is a significant test looked by the Indian little scope food handling industry. The nonappearance and deficiency of foundation offices to store crude materials bring down the quality and accessibility of the finished result. There are two different ways for legitimate capacity – warehousing and cold stockpiling. In distribution centres, issues emerge because of the shortage of room and how wares are ideally put away in that space. Item harms are another issue looked in a distribution centre; hardly any damages are unavoidable however can be diminished with a rack wellbeing netting and dodging over-burden of racks. Cold stockpiling for frozen food is a gigantic sub-industry all by itself. With always advancing food patterns, there are developing assortments of prepared to-eat food, drinks, handled frozen leafy foods items, marine and meat items, etc. – vast numbers of these things require particular stockpiling conditions. The absence of accessibility of these kinds of offices represents a significant requirement for the food preparing area in the food and beverage industry.

The food things should be distributed with appropriate bundling to keep away from breakages and harms during transportation. Likewise, the convenient conveyance is critical to evade deterioration – certain food things don’t keep going long regardless of whether put away in atmosphere controlled offices. (2)

In the Indian food preparing area, we stick to conventional creation measures where human evaluators are assessing the nature of agrarian and food items. This manual review is tedious, work concentrated and inclined to human blunder. To decrease the effect of these issues, the modernized evaluation of these items should be executed.

6. High competitors

This industry is profoundly serious with numerous significant parts in the coordinated, just as, disorderly areas. A couple of the top Indian Food Processors incorporate Nestle India Limited, Britannia Industries Limited, Amul India, Parle Agro Private Limited, Haldiram’s Food International Limited and ITC Limited. The food preparing industry can create through advertising channels, improving food quality norms and reinforce labour to confront worldwide difficulties to make due in a severe climate. Disregarding the issues encountered, food‐processing innovation in India has kept on gaining consistent ground towards modernization. The area will keep on seeing expansions in the quantity of food handling units. Some key drivers incorporate the section of worldwide organizations, accessibility of modest work power, rising interest of Indian items in global business sectors, and interest for prepared food.

7. Regulations

With an expanding number of guidelines and rules for food creation organizations to conform to, there is an everyday challenge to stay consistent and convey protected, reasonable and dependable nourishments to purchasers. With countless guidelines, not which are all clear, there is an actual weight set on food creation organizations. Changes in these guidelines frequently require quick reactions. It is imperatively significant that organizations can show their consistency. The European Union sets most of the standard food enactment. With Brexit not too far off, there are probably going to be sweeping changes that will require food makers to change how they work to meet another arrangement of guidelines. Food producing organizations should have the option to and meet all the administrative prerequisites simultaneously. It can expect them to change their methodologies and item advancement activities to meet guidelines to take measure to guarantee a mindful inventory network for food industry companies.

We have the experience, knowledge and ingredients portfolio to help you develop

Interested in learn more? Get in touch, we’d love to discuss your next project with you

Conclusion

For food and beverage industries, technology can be friend or foe. ERP systems that were implemented years ago can no longer support the complex demands of this industry. Food research lab explains the challenges in food product industries during production in this blog.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.