Dairy products, especially milk is highly perishable as it contains ample nutrition and high in moisture content for the microorganism to grow and multiply. To enhance food safety and protect the quality, non-thermal processing technologies are gaining significant attention in the Food Industry. Currently, consumers are opting for minimally processed foods that are close to natural tastes. Hence the dairy industries are moving towards non-thermal processing technologies which deliver fresh and nutritious foods with better shelf-stability. The microbial inactivation during the processing is critical for improving the shelf-life of milk. Common methods such as pasteurization, ultra-high temperature processing have been investigated in great depths to inactivate and destroy the pathogenic and spore-forming microorganisms. Researchers have worked closely on pathogenic organisms such as Listeria monocytogenes, Staphylococcus aureus, Escherichia coli, Bacillus cereus, Salmonella spp., Campylobacter spp, which are the major causes for the occurrences of foodborne illness worldwide.

Non-thermal technologies for Dairy Products

Introduction

Dairy products, especially milk is highly perishable as it contains ample nutrition and high in moisture content for the microorganism to grow and multiply. To enhance food safety and protect the quality, non-thermal processing technologies are gaining significant attention in the Food Industry. Currently, consumers are opting for minimally processed foods that are close to natural tastes. Hence the dairy industries are moving towards non-thermal processing technologies which deliver fresh and nutritious foods with better shelf-stability. The microbial inactivation during the processing is critical for improving the shelf-life of milk. Common methods such as pasteurization, ultra-high temperature processing have been investigated in great depths to inactivate and destroy the pathogenic and spore-forming microorganisms. Researchers have worked closely on pathogenic organisms such as Listeria monocytogenes, Staphylococcus aureus, Escherichia coli, Bacillus cereus, Salmonella spp., Campylobacter spp, which are the major causes for the occurrences of foodborne illness worldwide.

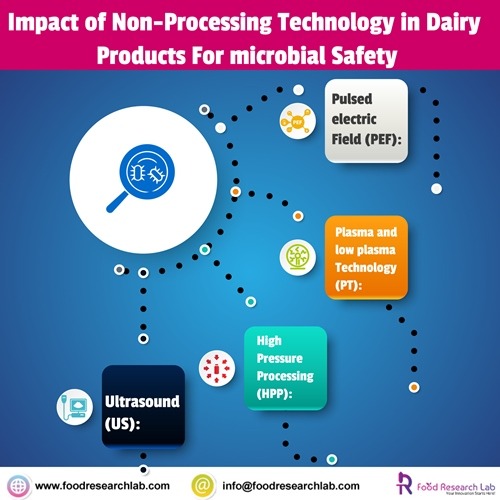

The main challenge with thermal treatments is that they damage some nutritional components while microbial inactivation, which also involves undesirable flavour changes. To avoid these nutritional and organoleptic changes, non-thermal treatments such as pulsed electric field (PEF), high-pressure processing (HPP), ultrasound, membrane filtration and non-thermal plasma have been deployed. (1)

Pulsed electric Field (PEF)

PEF has gained significant popularity as it destroys both spoilage and pathogenic bacteria and fungi. PEF also inactivates enzymes related to quality deterioration without causing any changes in flavour and taste. PEF treatment (35 kV/cm, 2.3 μs pulse width, at 65 °C for < 10 sec) shown significant pasteurization results similar to a high-temperature short time (HTST) pasteurization. Moreover, the sensory properties of PEF treated products were found to have a better consumer acceptance rate compared to the thermal counterparts.

Table 1 Effect of PEF on microbes present in dairy products. Adapted from 1

| Microorganisms | Dairy food | Treatment conditions | Reduction | References | |

| E. coli | Milk submitted to ultrafiltration | 50 pulses of 60 kV/cm or80 pulses of 70 kV/cm 36 kV/cm, 50 pulses | 6 and 9-log | Qin et al. (1998) | |

| L. innocua | Pasteurized skim milk | 200 μs at 50 kV/cm 15 to 28 °C, 0.5 L/min100 pulses, 50 kV/cm 0.5 μF,2 μsec, 3.5 Hz Exponential decay | 2.6-2.7-log | Fernández-Molina (2001) Fernández-Molina et al. (1999a) | |

| E. coli K12 | Raw bovine milk | 89 μs at 40 kV/cm at 32.5 °C | 5-log | Cregenzán-Alberti et al. (2015) | |

| E. Coli L. monocytogenes S. aureus | Raw whole milk UHT milk | 30 kV/cm after 200 μs 150 bipolar pulses of 8 μs at35 kV/cm | 2.1-Log 5-Log 4.5-Log | Zhao et al. (2013) Sobrino-López & Martin-Belloso (2006) | |

| L. lactis | Skim milk | 35 kV/cm, 90 μs, 22 °C | 1-log | Michalac et al. (2003) | |

| Salmonella Dublin L. monocytogenes (Scott A) | Skim milk Milk | K (x10-2/μs) = 0.054-0.52,15-40 kV/cm, Temp = 15-40 °C | 4-42.4 μs D value 150-200 μs D value | Sensoy et al. (1997) Reina et al. (1998) | |

| E. coli L. innocua B. subtilis L. delbrueckii P. fluorescens S. Dublin | SMUF Raw skim milk (0.2% milkfat) Milk | K (x10-2/μs) = 0.077-0.092,16 kV/cm, Temp < 30 °C | 2500-3000 μs D value 425-520 μs D value 4-7 Log | Pothakamury, (1995) Qin et al. (1994) Fernández-Molina et al. (1999b) | |

| Lactobacillus brevis | Yogurt | (50 °C, 1.8 V/μm | 2.0-log | Dunn & Pearlman (1987) | |

| B. stearothermophilus P. fluorescens | 3.4% fat milk | 60 kV/cm, 200μs, 50 °C (Tin) | 3-log | Shin et al. (2007) | |

| L. lactis | Skim milk | 35 kV/cm, 90 μs, 22 °C | 1-log | Michalac et al. (2003) | |

| Cronobacter sakazakii | Infant formula milk | 35 kV/cm, 500μs, 5 °C (Tin) | 1.2-log | Pina-Perez et al. (2009) | |

| L. innocua | 3.6% Fat whole milk | 29 kV/cm, 250 μs, < 45 °C | 1.5-2-log | Picart et al. (2002) | |

| L. innocua | Whole milk | 40 kV/cm, 43.75 μs, 68 °C | 5.5-log | Guerrero-Beltrán et al. (2010) | |

| S. aureus | Skim milk | 25 kV/cm, 100 μs, ~50 °C | 3-log | Sobrino-López & Martín‑Belloso (2008) |

High Pressure Processing (HPP)

HPP employs high pressure in the range of 100-600 MPa for up to 20 min duration to eliminate pathogenic and spoilage microorganisms to increase the stability and shelf life of food Product development. HPP can alter the protein characteristics depending on the duration of treatment and the temperature applied, creating irreversible changes in the structure. The particle size of skim milk decreases substantially from 200 to 100nm, when subjected to HPP treatment at 300MPa. HPP is also mainly chosen for minimal nutrient loss and significant microbial load reduction. To maintain the organoleptic properties of the milk, HPP treatment combinations could be used to provide an increased shelf-life and fresh sensory properties. (2)

Table 2 Effect of HPP on microbes present in dairy products. Adapted from 1

| Microorganisms | Dairy Food | Treatment conditions | Reduction | References |

| B. stearothermophilus | Skim milk | 84 °C at 300 MPa | 0.67-log | Pinho et al. (2011) |

| Bacillus spores | Commercial sterile milk | 300 MPa at 75-85 °C | ~5-log CFU/mL | Amador Espejo et al. (2014) |

| S. typhimurium Y. enterocolitica E. coli S. aureus L. monocytogenes P. fluorescens | Milk | K (1/min) = 0.768, 350 MPa 0.768, 375 MPa 2.303,300 MPa 3.838, 345 MPa | 3 min D value 0.6 min D value | Patterson et al. (1995) Patterson & Kilpatrick (1998) Gervilla et al. (1997) Kalchayanand et al. (1998) |

| S. typhimurium | Raw milk | 25 °C, 300 MPa | 9.21 min D value | Erkmen, (2009) |

| C. sporogenes | Milk | 90 °C, 700 MPa | 13.6 min D value | Shao & Ramaswamy, (2011) |

| E. coli MG1655 L. innocua S. aureus | Raw milk with 15% fat | 300 MPa, 25 °C 100 MPa, 2-4 °C | 1.2 to 4.0-log | Briñez et al. (2007) |

Ultrasound (US)

The US technology is the most commonly used technology in the food industry around the globe as it is eco-friendly, non-toxic and showcases various applications in the food industry. The US is greatly used in the homogenization and inactivation of microbes (via sonication) present in milk and in novel dairy products which have unique physio-chemical functional properties. The use of the US in the food industry is limited compared to the other non-thermal processing techniques. However, the US can be used in the removal of gases and homogenization of fat and also improve the availability of antioxidants.

Table 3 Effect of US on microbes present in dairy products. Adapted from 1.

| Microorganisms | Dairy Food | Treatment conditions | Reduction | References |

| E. coli | Raw whole 4% fat cow’s milk | 20 kHz, 120 μm,12 min, 60 °C | 3.1-log | Herceg et al. (2012) |

| E. coli P. fluorescens L. monocytogenes | Raw milk (pasteurization) | 20 kHz, 10 min, 750 W | 2 to 5.34-log CFU/g | Cameron et al. (2009) |

| L. monocytogenes | UHT milk | Heat at 60 °C with Sonication at 20 kHz | D60&S = 0.3 min | Earnshaw et al. (1995) |

| S. typhimurium | Skim milk | 30 min at 50 °C 30 min at 40 °C | 3-log 2.5-log | Wrigley and Llorca (1992) |

| E. coli K12DH5 | UHT milk (pH 6.7) | 110 μm, 60 °C | D60&S = 23s | Zenker et al. (2003) |

Plasma and low plasma Technology (PT)

PT is the newest addition to the non-thermal technologies, having various application to the food and dairy industry. PT has proven to improve the quality of the end product with enhanced microbial safety from both pathogenic and spoilage microbes. Just like HPP and PEF, PT has also shown to preserve the sensorial, organoleptic and nutritional properties of the foods. The mechanism of PT is based on the additional gas energy which is getting fed by electrical discharge turning it into energy-rich plasma. Plasma consists of free radicals and electrons which is highly reactive. Moreover, it is important to note that PT induces modification on the surface of the food as the radicals react on the surface and are not capable of penetrating the matrix. PT is also used for enzyme modification and inactivation, wastewater treatments and modified food packaging.

Conclusion

The operational cost of HPP continues to decrease due to its increased demand in the industry. The average processing cost of HPP ranges between 0.05 to 0.5US$ per kg of food. The operational cost of PEF ranges between 0.01 to 0.02 US$ per litre of food. This cost of non-thermal techniques operation is 10 times greater than conventional thermal processing cost. US technology can be used cost-efficiently for extraction and rapid crystallization procedures, providing increased yield in less time. Moreover, the current limitations with non-thermal processing technologies are that it involves huge investment and lack regulatory support in a few countries.

To sum, although these novel non-thermal technologies are capable of reducing the microbial load similar to thermal processing techniques, with an added benefit of minimal loss of nutritional contents. A combination of these techniques called hurdle technology can be used to obtain massive results, such as destroying pathogenic microbes which is not possible otherwise. Therefore, there is great scope in the near future for these techniques to go mainstream; however, manufacturers should look into the drawbacks which are holding them back.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.